Каталог TooTool техническая информация 1 - страница 143

Навигация

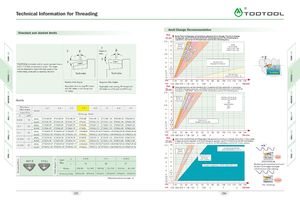

Technical Information for Threading A\ 0 Anvil Change Recommendation Standard and slanted Anvils PitchTPI mm ) ^ Some Pitch to Diameter combinations require an Anvil change. If an Anvil changeis required, use STM-R Anvils for EX-RH toolholders and for IN-LH boring bars. Use STM-L Anvils for IN-RH toolholders and for EX- LH boring bars. 2.5 10 YNegativeHelix 9383.57 IPSpecialHolderRequired & ACMESTUBACMETRAPEZ (DIN 103)ROUND (DIN 405) TOOTOOLtoolholder and boring bar pockets have a 4 655 7 £3 / Standard Anvil(Supplied With Holder) built-in 1.5 helix compensation angle. This anglemay be adjusted to match the helix angle of thethread being produced by replacing the anvil.Toolholder Toolholder 6810121643.532.521.5 //7/UL7 Change to anvilSTM-R 1Nor STM-L 1N Positive Helix Angles Negative Helix Angles mm: 5 10 20 30 40 50 60 70 80 90 100 110 120 130 140 Inch: 0.25 0.50 0.75 1 1.25 1.50 2 2.50 3 4 5 Diameter Applicable when turning RH thread Applicable when turning RH thread withwith RH holder or LH thread withLH holder or LH thread with RH holder.LH holder. Pitch TPI mm ^ ^ Most applications use the standard Anvil supplied with the toolholder or boring bar. If an Anvil change is required, use STM- R Anvils for EX-RH toolholders and for IN-LH boring bars. Use STM-L Anvils for IN- RH toolholders and for EX- LH boring bars. 2.5 10 § T 9 Special /y §j&rsf [tj"-/ / % PARTIAL PROFILES 60 AnvilsResultantHelix Angle 4.5 ° 3.5 ° 2.5 ° 1.5 0 0.5 ° 0 0 - 0.5 0 - 1.5 0Holder 3 8 HolderRequired*A£"K#%&7/f/7/7d•&3.57 PARTIAL PROFILES 55isoUNWHITWORTHNPT4603 M SCo&CoBSPT Insert Size Ordering Code 5 5 / d Lmm 9.525 16 ER /NL STM16R-3P STM16R-2P - STM16R 1P STM16R STM16R -1N - STM16R 1.5N - STM16R 2N STM 16 R - 3N 6 43.5 / / Standard Anvil EL/NR STM16L-3P STM16L-2P STM16L-1P STM16L STM16L-1N STM16L-1.5N STM16L-2N STM16L-3N12.722ER/NLSTM22R-3PSTM22R-2PSTM22R-1PSTM22RSTM22R-1NSTM22R-1.5NSTM22R-2NSTM22R - 3N83102.5/ (Supplied With Holder)122 EL/NR STM22L-3P STM22L-2P STM22L-1P STM22L STM22L-1N STM22L-1.5N STM22L-2N STM 22L -3N 16 1.5 12.7 22 ER/NL STM22UR-3P STM22UR-2P STM22UR-1P STM22UR STM22 UR - 1N STM22UR-1.5N STM22UR-2N STM22UR-3N mm: 5 10 20 30 40 50 60 70 80 90 100 110 120 130 140 EL/NR STM22UL-3P STM22 UL- 2 P STM22UL-1P STM22UL STM22UL-1N STM22UL-1.5N STM22UL-2N STM 22UL -3 N Inch: 0.25 0.50 0.75 1 1.25 1.50 2 2.50 3 4 5 Diameter 15.875 27 ER/NL STM27R-3P STM27R-2P STM27R-1P STM27R STM27R -1N STM27R-1.5N STM27R-2N STM27R - 3NEL/NRSTM27L-3PSTM27L-2PSTM27L-1PSTM27LSTM27L-1NSTM27L-1.5NSTM27L-2NSTM27L-3NPitchAMost American Buttress and Sagengewinde applications and anvil change. Note that in many cases,TPI mma negative anvills . required If an Anvil change is required, use STM -R Anvils for EX- RH toolholders ER /NL STM27UR-3P - STM27UR 2P - STM27UR 1P STM27UR STM27UR -1N STM27UR-1.5N - STM27UR 2N - STM27UR 3N15.87527 and for IN-LH boring bars. Use STM - L Anvils for IN-RH toolholders and for EX-LH boring bars.2.510 EL/NR STM27UL-3P STM27UL-2P STM27UL-1P STM27UL STM27UL-1N STM27UL-1.5N STM27UL-2N STM27UL-3N 938 SpecialHolderRequiredmff */s c AMERICAN BUTTERSSSAGENGEWINDE (DIN 513) Cod Standard Anvil Ec SMT- R(O~o LO Insert d 9.525 12.7 15.875Q)SizeL162227U) 3.5 4c5occcXHolderER /NLEL/NRER /NLEL/NRER / NLEL/ NR (SuppliedWith Holder) Before Anvil changeChange to negative anvil STM-R3N or STM-L 3NReplacing the standard anvil withan anvil with negative anglewill eliminate side rubbing 6 CO 0)X Ordering Code STM16R STM16L STM 22 L STM 22 R STM 27 L STM 27 R 8 ^Standard anvil has lead angle 1.5° 101216 = 3.74[ Y—1-5CorrectiNegative anvil mm: 5 10 20 30 40 50 60 70 80 90 100 1 10 120 130 140 After Anvil change Inch: 0.25 0.50 0.75 1 1.25 1.50 2 2.50 3 4 5 Diameter 285 286

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2