Каталог TooTool техническая информация 1 - страница 14

Навигация

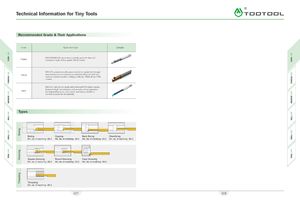

Technical Information for Tiny Tools A\ Recommended Grade & Their Applications Grade Application Type Sample P20-P30 K20-K30, general use carbide grade for tiny tool TTIM45 medium to high cutting speed, TiALN coated K10-K20, premium multipurpose submicron grade for stronger TTIS30 wear resistance and improved productivity. Ideal for steel andstainless steel in unstable cutting conditions. AITiN alloyed PVD coated. K10-K20. Sub-micron grade with advanced PVD triple coating. Extremely high heat resistant and smooth cutting operation, N400 for high performance, and normal machining conditions. General purpose for all materials. Types O) s g CQ Boring Copying Back Boring Chamfering Min. dia. of machining : 03.2 Min. dia. of machining : 04.2 Min. dia. of machining : 03.2 Min. dia. of machining : 04.2 i5. H3E § oe Square Grooving Round Grooving Face Grooving Min. dia. of machining : 03.2 Min. dia. of machining : 03.2 Min. dia. of machining : 06.0 I *2-C Threading Min. dia. of machining : 03.3 027 028

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2