Общий каталог Sumitomo 2019 - 2020 - страница 53

Навигация

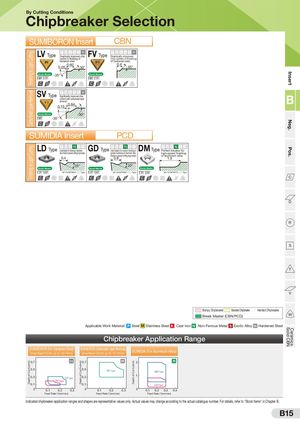

Finishing to Light CuttingCarburised Layer RemovalFinishing to Light CuttingDepth of Cut ap (mm) Depth of Cut ap (mm) Depth of Cut ap (mm) CeramicsSolid CBNPos.Neg.Insert By CutCCCtingDDD CRRRondSSSitioTTTnsVVV WWW C D R S T V WCDRSTVW Chipbreaker CCC DDD RRR SSS TTT VVV WWW C D R C D R Selection S T V W C D R S T V S T V W W pe AX EMAY SUMCCC IDDDBTOyRRRpeRSSS OTTTNVVVInWWWserCCt D R S T V WD CBN TyRpTeySpe T V W C D R S T V WAXType AY Type 2.500.05 LCCCV D R DDTypRRe SSDSPr3as0Mti2°cTTTa.l5lyK0impNVVVroveSdWWWchHip FCCV DDTypRRe0.05DSSPrasMticTTa2lKly.52im0N.VV15p5ro°SveWWdH C D R S T 2.V50 W30° 2.515° control in finishing of chip control in finishing hardened steel. of hardened steel. CCC DDD RRR 0SSS.05 TTT0.60VVV 3WWW0° CC DD RR S 0T.4 V WST45°VW C D R S T V W Break Master -35° Break Master 0C° 7D°CCDDRRR SSS TTT VVV WWW 0C° 7D° R S T V WCDRSTVW C D R S T V W ype SRVH CCC Type DDDTyRRRpeScSSSPoignntrifoMicl awTTTnitthlKycimarpbNVVVruorviseeSddcWWWlhaiyHper GFHB C D R S C D TRyTpyeSpe TT VV WW C RLHB D R S T TyTpyepe V W FB Typeremoval LB Type B 3.503° C D R 00..S3105CCDDRR -15SS°Break MasterTTT0.84VVV13WWW50°° C D R 3°S 0.T530.50V WCDRSTV2W0° C D R S 0.3T0 0.8V0 W 15°-15°15° 0.50 20° 0.80 15° 0° -35° C DCCDD(mm)RRRSSS TTT VVV WWW C D R S T V WCDRSTVW C D R S T V W 6 SUMIDIA CC DDep4th Dd of RCut R SS C epD2 R S InTTT sVVVerWWWt C D R S PT CV DWCDRSTVW C D R S T V W ype LLDDType CCCth D0DD PMK N S HRRR SSS TTT VVV WWW TypeF0Iadle.leo2eayldtbhraeRnakkasetrteofosr(pmfienc0imsia.hl4i/ncrguetotvifn)agluemdgineusmha0p.e6GGDD P C D TyTRpyepeISdeal M breakTerK N for meVdium S H finisWhing toCDRS T V W general machining of aluminum alloythanks to special cutting edge shapeDMLD C D TyRpeTyPSPperefMecTt K N S H breaVker fWorhigh-speed finishingof aluminum alloy 0.8 0.4 0.8 10.5.4 20° C D RCCBreak DDMasterRRSSSTTTVVV25°WWW C D R S T V 20W°CBreak DMasterRSTVW C D R S T V W25°Break Master 7° 11° NF-CCMT0602 ○○ Type 7° 11° NF-CCMT0602 ○○ Type 7° 11° NU-CCMT09T3 ○○ Type CCC DDD RRR SSS TTT VVV WWW C D R S T V WCDRSTVW C D (mm) R S T V W6Relief Angle7° Pos. C Dep4th of Cutd 11° Pos. CCC DDD RRR SSS TTT VVV WWW C D R S T V WCDRSTVW C ep D2 R S T V Wth0 0.2 0.4 0.6Feed Rate (mm/rev) D umpy Insert StandarCCd BDDreaRkRer SSHaTTndeVVd BWWreakeCr D R S T V W C D R S T V WBumpy InsertStandard BreakerHanded Breaker reak Master (CBNCC/PCDDD)RR SS TT VVFoWWr ChaCmfDeriBnRgreSak TMaVsteWr (CBCN/DPCRD) S T V FWor Chamfering R CC DD RR SS TT VV WW C D R S T V W C D R S T V W S CC DD RR SS TT VV WW C D R S T V W C D R S T V W C D R S T V W C D R S T V W C D R S T V W T C D R S T V W C D R S T V W C D R S T V W C D R S T V W C D R S T V W C D R S T V W V C D R S T V W Bumpy Chipbreaker Standard Chipbreaker Handed Chipbreaker Break Master (CBN/PCD) W Applicable Work Material: P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel Chipbreaker Application Range SUMIBORON (For Hardened Steel)(Inscribed Circle up to 12.7mm) SUMIBORON (Carburised Layer Removal)(Inscribed Circle up to 12.7mm) SUMIDIA (For Aluminum Alloy) 0.7 H 0.7 H 2 N 0.5 0.5 SV Type GD Type 0.3 LV Type 0.3 1 FV Type 0.1 0.1 LD Type 0 0.1 0.2 0.3 0 0.1 0.2 0.3 0 0.1 0.2 0.3 0.4 Feed Rate f (mm/rev) Feed Rate f (mm/rev) Feed Rate f (mm/rev) Indicated chipbreaker application ranges and shapes are representative values only. Actual values may change according to the actual catalogue number. For details, refer to "Stock Items" in Chapter B. B15

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019