Общий каталог Sumitomo 2019 - 2020 - страница 52

Навигация

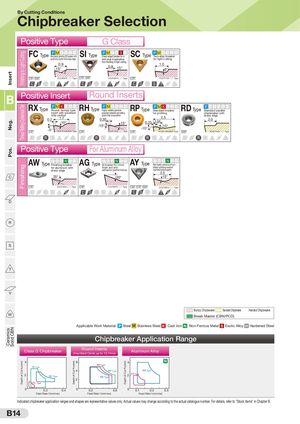

InsertNeg.Pos.CeramicsSolid CBN Finishing to Light CuttingThread Roling Cylindrical DieFinishingDepth of Cut ap (mm) Depth of Cut ap (mm) Depth of Cut ap (mm) 1.15 5° 2.0 25° By CutCCCtingDDD CRRRondSSSitioTTTns1VVV5° WWW CCC DDD RRR SSS TTT VVV WWW CC DD RR SS TT VV WW C D R S T V W Chipbreaker CCC DDD RRR SSS TTT VVV WWW CC DD RR C D R Selection SSS TTT VVV WWW CCC DDD RRR SSS TTT VVV WWW C D R S T V W 1.505° MMUM C FP CCTypDDe RRTypSSe TT VV WW CCTypDDe RR SS TT VV WW CC DD TyRRpe SS TT VV WWMMPEoFMsCitive Type C SAIX G ClassFSPCAY Ty0pCCCC.1e50T.DDDD1y5Tpye2pRRRR.e90512.Pg10SS.SSoeP5o9r°idp5hcehMriaplTTTTcgorinn2Ktdr.ion0lgaNn30VVVV1dD4sbhreSa°arpkWWWWeerdHwgeith C Type CCC D R S2.15T V W 0.15 0DTD.D1y5TpyeRRRp2e.1SwSSSP5hi1daer4pMra°endTTgTgeeKdofbarpNeVVVpaklicearStfiooWrWnWasHCCCDDD 0.10RRR05°SSS 21.55TTT0°.9 VVVWWWCCCDDDRRR 14°fSSSro3m0fi2n°0isTT.Th.5i8n0g toVVVli1gh5t c°uWWWtting.CDRS 1.4T0VWCCCTDDDyTpyepRRReT1y.SSSTfpP4owr0eoMli-gsTTThtetKpcu1bNtVV0Vrtein°ag1Sk0eWWWr°HCCCDDDRRRSSS1TT.0 T 26.°1VVV55° WWWCDRSTVWCDRSTVWCDRSTVW 7CCC° (mm161)DDD° RRR SS TT VV CCGT09T3 WW ○○ TypeSTVRelief W Angle 7CC° 11DD°CDRRR SS TT VV CCGT09T3 WW ○○ TypeSTV W 7CC° DD RR SS T V TCGT1103 W ○○ TypeTVWCDRSTVW C D R S T V W 7° Pos. B FPWositive CCCDep4th of Cut d D R e D R p 2D R Tt ype Insert SS TT 11VV°Pos.WW S T V W SSCCC Round DD RR SS TT TDypeR S T InseUrtJs VV WW CC (mm) DD6 V W C D Dep4th d RR SS ofTCRuytpeS TTT VVVR7°ePlieofWWWsA.ngle C RDDR S Type T V Wh0e AW Type FWGRHX SSRRHH URJPFB 0.2 0.4 0.6TyCCCpe Type DDDTyp0.eRRR90FeeRicSSSnPdhosRiuepaMrntetcdTTT(owm,1nKmibtt5h/urroe°meNvVVVl)xpcyeStlylWWWepnHetCC0DD.903RR° 0.2SS 3.5TT011.70°VVWWCDRS 15T°VW7°-5°RCMT1606MON TypeCCCTypDDDeTyTpyRRRepe1.Hp1SSSPui5grphloyMsreeTTTlbiarKebal5ekeg°rNeVVVpneroravSild- iWWWngHgood chip evacuationCCCDDD1RRR.15-105.SS3S°0 5TT°TVV1W5W°VW7°RCMT1606 ○○ TypeCCCpth Type D2 R TDD0ypeRRTy0FSfSSSp.eoP2teraedpnRMdraotTTTaefri(Kldmi0nm.b4g/NrrVVVeeva) kSeWWWr 0H.6CCCDD 0RR.25 D-15°R SSS1.004.TTT520.155°VVVWW2W0°7°RCMX1606MON Type RRDDLB CDTyTpRyepeScTSPhtyaipnpMbderTaeraK2dk.pe0NraVrwailStlehWl Hsharp edge2.0 0.80CDRSTVW15°11°RCMT1604 ○○ TypeAW Type25°25° CC DD RR SS TT VV WW CC DD RR SS TT VV WW CC DD RR SS TT VV WW C D R S T V W C D R S T V W C D R S T V W C D R S T V W (mm) Positive 6 CCC D Dep4th D d D e of CuRRtR Type SSS TTT VVV WWW CCC DDFoRRr D R ASSSlumTTT inVVVumWWW EGMAADWW AALXGD Type CCCTypth pDDDT20eypTeRRRyp0Fe.eFfs2SSSePohidnraRiasrMaplhtueiTTTmen(mdKg0imng.4b/uererNmVVVveR7)°aewPlkiSeoeiftsArWWWh.0nH.6gle CC TDDyTpTyeyRpRpee C D R AfaSSSiPndl ihbserhMesaaiTToTknnedKrpafeonNrVVVrtfio-mrmiSrraoWWWnrHce (mm) Alloy6 C D C D Dep4th of RR Cut SS TT VV WW C d D e R S T V W AAYYType p 2 C th C DD0 C D P M K NR7°ePlieoSfsA.ngHle R S T V W TypeHigh-quality ground aluminum RR SS TT VV WW 0F.e2bmeraedcahkRienaretadecsh(muie0rvfm.ai4nc/gereeqvxu)caeliltlyent0.6 C D R S T V WCDRSTVW 2.0 C EM TypCCe 0DD.05 RR 02.8.50SS25°TT20VV° AWW X CCTypDDe 20.540RR 30SS°TTV2V205°°WW AYCC TDDypeRR SS 2.5TT15°VVWW C D R S T V W C D 2R.50 S T V W C D R2.5S0 T V W C D R S2.5 T V W 70°.05 VCGT1604 ○○ Type 7° CCGT09T3 ○○ Type 5° 7° 11°30° 15CC°GT09T3 ○○ Type CC DD RR SS TT VV WW CC DD RR SS TT VV WW CC DD RR SS TT VV WW C D R S T V W C D R S T V W C D (mm) R S T V W C D R S T V W D 6 Relief Angle C D R S T V W C D Dep4th of C D d CutRRe SS TT V7V° PosW.Wp2 CCC DDD RRR SSS TTT VVV WWW C D R S T V W R GH Type C D R S T V W RHt hCC0TDDypeRR 0.2SS Feed Rate 0.4 TT VV (mm/rev) WW0.6 FB CC DD TRRypeSS TT VV WW LB TypeCDRST V W S GH Type C3° RH Bump3y.5In0sert Standard Break0.e3r0 3° DBre3Ra.5k0SMaTsteVr (CWBN/CCTPyCpDDe0D.3-)01RR5° FB Handed BreakeCr D R S0.50T SS TT V1VF5o° rWWChaCCCmfTDDDeyrpineRRR0g.50SSS TTT VVV20° V -15° 15° C D R S T V W C D R S T20°V WWWWW LB Type 0.80CDR0S.80 TVW15°15° C D R S T V W C D R S T V W T GD Type LD Type C D R S T V W GD Type 0.8 LD Type 0.4 20° 25° 80 V 0.8 0.4 C D R S T V W 15° 20° 25° C D R S T V W Bumpy Chipbreaker Standard Chipbreaker Handed Chipbreaker W Break Master (CBN/PCD) Applicable Work Material: P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel Bumpy Insert Standard BreakeCr hHainpdbedrBeraeakkeer r Application Range Break Master (CBN/PCD) For Chamfering ClaBBsursemGapkCy hMInipsabesrrettaekrSe(trCanBdNar/d(PInBsCcrriDebRae)odkuCenirrcdleHIunpasnteordt1se2F.d7omBrmr)Ceahkaemr feArliunmginum Alloy 4 6 4 N RH Type SI Type 4 RP Type AG Type 2 SC Type RX Type 2 AY Type 2 FC Type 0 0.2 0.4 0 0.2 0.6 0 0.1 0.3 0.5 Feed Rate f (mm/rev) Feed Rate f (mm/rev) Feed Rate f (mm/rev) Indicated chipbreaker application ranges and shapes are representative values only. Actual values may change according to the actual catalogue number. For details, refer to "Stock Items" in Chapter B. B14

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019