Общий каталог Sumitomo 2018 - 2019 - страница 565

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

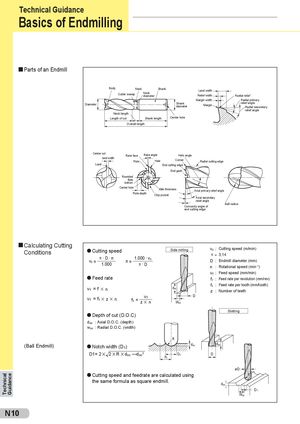

Technical Guidance Basics of Endmilling Parts of an Endmill Body Neck ShankCutter sweepNeckdiameterLand widthRelief width Radial relief Margin width Radial primary Diameter Shankdiameter Margin relief angleRadial secondary relief angle Neck length Length of cut Shank length Center hole Overall length Center cut Rake face Rake angle Helix angle land width Flute Heel Corner Radial cutting edge Land End cutting edge End gash Rounded flute bottom Center hole Web thickness Axial primary relief angle Flute depth Chip pocket Axial secondary relief angle Ball radius Concavity angle of end cutting edge Calculating CuttingConditionsl Cutting speed Side millingvc =π.D.n1.000n=1.000 . vcπ.Dvc :Cutting speed (m/min)π≈3,14D:Endmill diameter (mm)n:Rotational speed (min-1) vf : Feed speed (mm/min) l Feed rate fr : Feed rate per revolution (mm/rev) vf = f 5 n doc ft : Feed rate per tooth (mm/tooth)z:Number of teeth vf = ft 5 z 5 n ft = vfz5n DWoc Slotting l Depth of cut (D.O.C) doc : Axial D.O.C. (depth) woc : Radial D.O.C. (width) R (Ball Endmill) l Notch width (D1) doc doc D1= 2 5 2 5R 5doc —doc2 Pf D1 D øD l Cutting speed and feedrate are calculated using R the same formula as square endmill. doc D1 Woc N10 Technical Guidance

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части