Общий каталог Sumitomo 2018 - 2019 - страница 314

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

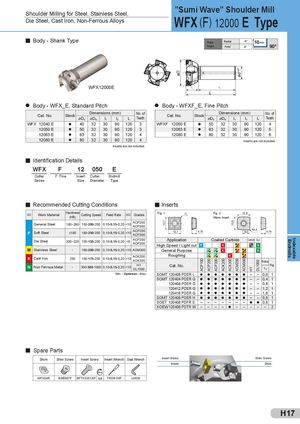

Shoulder Milling for Steel, Stainless Steel, ”Sumi Wave” Shoulder Mill Die Steel, Cast Iron, Non-Ferrous Alloys WFX (F) 12000 E Type Body - Shank Type Rake Radial -8° 10 mm P Angle Axial 8° 90° WFX12000E l1 l2 Body - WFX_E, Standard Pitch Body - WFXF_E, Fine Pitch Cat. No. Stock ØDc Dimensions (mm)ØDsl1l2 L No. ofTeeth Cat. No. Stock ØDc Dimensions (mm)ØDsl1 l2 L No. ofTeeth WFX 12040 E l 40 32 30 90 120 3 WFXF 12050 E l 50 32 30 90 120 4 12050 E l 50 32 30 90 120 3 12063 E l 63 32 30 90 120 5 12063 E l 63 32 30 90 120 4 12080 E l 80 32 30 90 120 6 12080 E l 80 32 30 90 120 4 Inserts are not included. Inserts are not included. Identification Details WFX F 12 050 E Cutter F: Fine Insert Cutter Endmill Series Size Diameter Type Recommended Cutting Conditions Inserts ISO Work Material Hardness (HB) Cutting Speed Feed Rate DOC Grades Fig. 1 Fig. 2 12,8Wiper Insert General Steel 180~280 150-200-250 0,10-0,15-0,20 <10 ACP200ACP300 P Soft Steel ≤180 180-250-350 0,10-0,15-0,20 <10 ACP200ACP300 12,7 4,76 6,5 R0,8 4,76 Die Steel 200~220 100-150-200 0,10-0,15-0,20 <6 ACP200ACP300 Application Coated Carbide Carbide DLCHigh Speed / Light cutPKMSKNN M Stainless Steel - 160-200-250 0,10-0,15-0,20 <10 ACM300 General Purpose PM PM K MS MS N K Cast Iron 250 100-175-250 0,10-0,15-0,20 <10 ACK200ACK300 Roughing PM PM K MS Radius N Non Ferrous Metal - 300-500-1000 0,10-0,15-0,20 <10 H1DL1000 Cat. No. Fig. Min. - Optimum - Max. SOMT 120408 PDER L – – 0,8 1 SOMT 120404 PDER G – – 0,4 1 120408 PDER G – – 0,8 1 120412 PDER G – – 1,2 1 120416 PDER G – – 1,6 1 SOMT 120408 PDER H – – 0,8 1 SOET 120408 PDFR S – – – – – – – 0,8 1 XOEW 120408 PDTR W – – – – – – – – – 2 Spare Parts Shim Shim Screw Insert Screw Insert Wrench Seat Wrench Insert Screw Shim Screw Insert Shim WFXS4R BW0507F BFTX03512IP 3,0 TRDR15IP LH035 H17 12,7 ACP100 ACP200 ACP300 ACK200 ACK300 13,0 ACM200 ACM300 H1 DL1000 Endmills Indexable

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части