Общий каталог Sumitomo 2018 - 2019 - страница 284

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

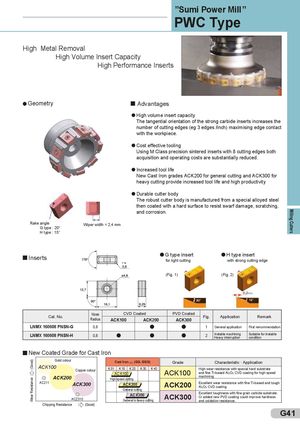

Milling Cutters ”Sumi Power Mill” PWC Type High Metal Removal High Volume Insert Capacity High Performance Inserts Geometry Advantages l High volume insert capacity The tangential orientation of the strong carbide inserts increases the number of cutting edges (eg 3 edges /inch) maximising edge contact with the workpiece. l Cost effective tooling Using M Class precision sintered inserts with 8 cutting edges both acquisition and operating costs are substantially reduced. l Increased tool life New Cast Iron grades ACK200 for general cutting and ACK300 for heavy cutting provide increased tool life and high productivity l Durable cutter body The robust cutter body is manufactured from a special alloyed steel then coated with a hard surface to resist swarf damage, scratching, and corrosion. Rake angle G type : 20° Wiper width = 2,4 mm H type : 15° Inserts G type insert H type insertfor light cuttingwith strong cutting edge (Fig. 1) (Fig. 2) Cat. No. Nose CVD CoatedRadiusACK100ACK200 PVD Coated Fig. ApplicationACK300 Remark LNMX 160608 PNSN-G 0,8 l l 1 General application First remommendation LNMX 160608 PNSN-H 0,8 l l l 2 Instable machiningHeavy interruptionSuitable for instablecondition New Coated Grade for Cast Iron Gold colour Cast Iron (K) (GG, GGG) Grade Characteristic · Application ACK100 Copper colourACK200 K 01 K 10 K 20 K 30 K 40 High wear resistance with special hard substrateAC K100High speed cuttingACK100and fine Ti-based Al2O3 CVD coating for high speedmachining AC211 ACK300 AC K200 ACK200 Excellent wear resistance with fine Ti-based and toughAl2O3 CVD coating General cutting ACZ310 AC K300General to heavy cutting Excellent toughness with fine grain carbide substrate.ACK300Cr added new PVD coating could improve hardnessand oxidation resistance. Chipping Resistance (Good) G41 (Good)Wear Resistance

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части