Каталог Stellram твердосплавные цельные фрезы - страница 45

Навигация

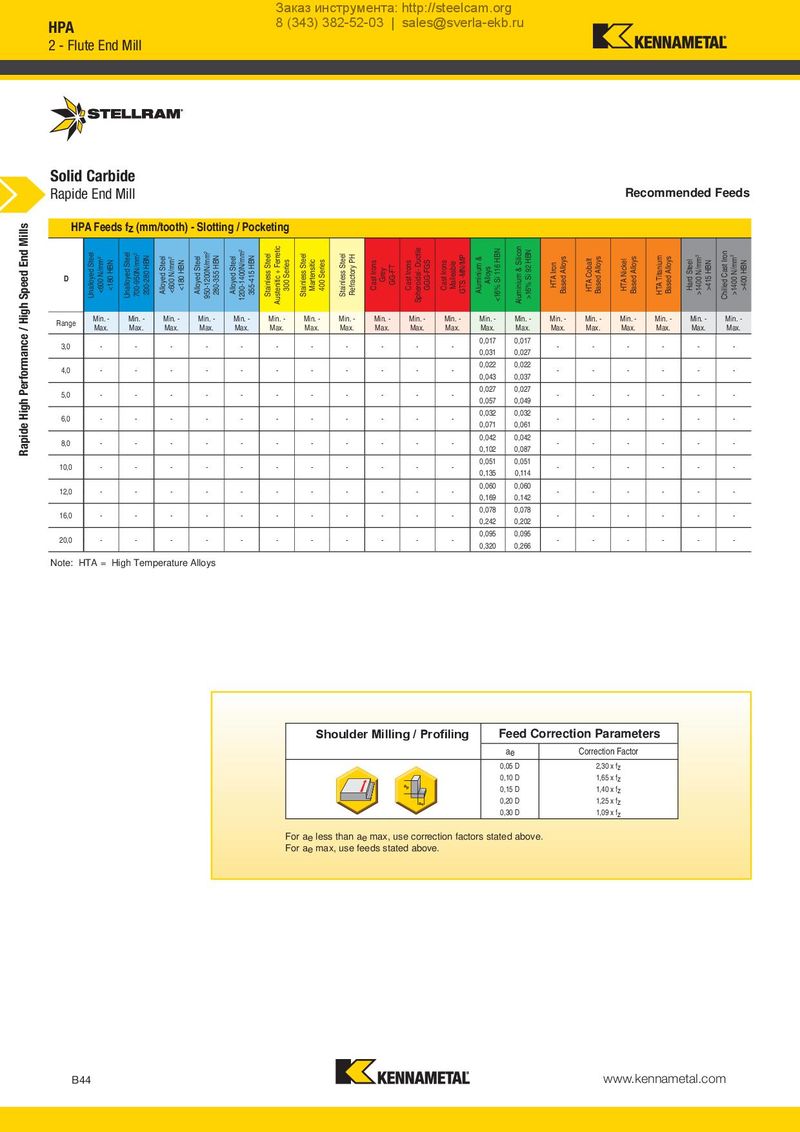

Заказ инструмента: http://steelcam.org HPA 8 (343) 382-52-03 | sales@sverla-ekb.ru 2 - Flute End Mill Solid Carbide Rapide End Mill Recommended Feeds High Speed End Mills HPA Feeds fz (mm/tooth) - Slotting / Pocketing D Unalloyed Steel <600 N/mm2 <180 HBN Unalloyed Steel 700-950N/mm2 200-280 HBN Alloyed Steel <600 N/mm2 <180 HBN Alloyed Steel 950-1200N/mm2 280-355 HBN Alloyed Steel 1200-1400N/mm2 355-415 HBN Stainless Steel Austenitic + Ferretic 300 Series Stainless Steel Martensitic 400 Series Stainless Steel Refractory PH Cast Irons Grey GG-FT Cast Irons Spheroidal- Ductile GGG-FGS Cast Irons Malleable GTS -MN/MP Aluminium & Alloys <16% Si 116 HBN Aluminium & Silicon >16% Si 92 HBN HTA Iron Based Alloys HTA Cobalt Based Alloys HTA Nickel Based Alloys HTA Titanium Based Alloys Hard Steel >1400 N/mm2 >415 HBN Chilled Cast Iron >1400 N/mm2 >400 HBN Range Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - Min. - / Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Max. Performance 3,0 - - - - - - - - - - - 0,017 0,017 - - - - - - 0,031 0,027 4,0 - - - - - - - - - - - 0,022 0,022 - - - - - - 0,043 0,037 5,0 - - - - - - - - - - - 0,027 0,027 - - - - - - High 0,057 0,049 6,0 - - - - - - - - - - - 0,032 0,032 - - - - - - Rapide 0,071 0,061 8,0 - - - - - - - - - - - 0,042 0,042 - - - - - - 0,102 0,087 10,0 - - - - - - - - - - - 0,051 0,051 - - - - - - 0,135 0,114 12,0 - - - - - - - - - - - 0,060 0,060 - - - - - - 0,169 0,142 16,0 - - - - - - - - - - - 0,078 0,078 - - - - - - 0,242 0,202 20,0 - - - - - - - - - - - 0,095 0,095 - - - - - - 0,320 0,266 Note: HTA = High Temperature Alloys Shoulder Milling / Profiling Feed Correction Parameters ae Correction Factor 0,05 D 2,30 x fz 0,10 D 1,65 x fz ap 0,15 D 1,40 x fz ae 0,20 D 1,25 x fz 0,30 D 1,09 x fz For ae less than ae max, use correction factors stated above. For ae max, use feeds stated above. B44 www.kennametal.com

Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы