Общий каталог SGS 2021 - страница 293

Навигация

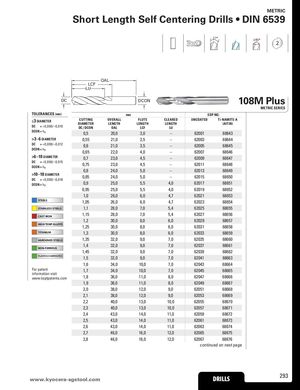

METRIC Short Length Self Centering Drills • DIN 6539 27° 145° 2 OAL LCF LU DC DCON 108M Plus METRIC SERIES TOLERANCES (mm) mm EDP NO, ≤3 DIAMETER CUTTING OVERALL FLUTE CLEARED UNCOATED Ti-NAMITE-ADIAMETERLENGTHLENGTHLENGTH(AlTiN) DC = +0,000/–0,010 DC / DCON OAL LCF LU DCON = h6 0,5 20,0 3,0 – 62001 68643 >3–6 DIAMETER 0,55 21,0 3,5 – 62003 68644 DC = +0,000/–0,012 0,6 21,0 3,5 – 62005 68645 DCON = h6 0,65 22,0 4,0 – 62007 68646 >6–10 DIAMETER 0,7 23,0 4,5 – 62009 68647 DC = +0,000/–0,015DCON = h6 0,75 23,0 4,5 – 62011 68648 0,8 24,0 5,0 – 62013 68649 >10–18 DIAMETERDC= +0,000/–0,018 0,85 24,0 5,0 – 62015 68650 DCON = h6 0,9 25,0 5,5 4,0 62017 68651 0,95 25,0 5,5 4,0 62019 68652 1,0 26,0 6,0 4,7 62021 68653 STEELS 1,05 26,0 6,0 4,7 62023 68654 STAINLESS STEELS 1,1 28,0 7,0 5,4 62025 68655 CAST IRON 1,15 28,0 7,0 5,4 62027 68656 1,2 30,0 8,0 6,0 62029 68657 HIGH TEMP ALLOYS 1,25 30,0 8,0 6,0 62031 68658 TITANIUM 1,3 30,0 8,0 6,0 62033 68659 HARDENED STEELS 1,35 32,0 9,0 7,0 62035 68660 1,4 32,0 9,0 7,0 62037 68661 NON-FERROUS 1,45 32,0 9,0 7,0 62039 68662 PLASTICS/COMPOSITES 1,5 32,0 9,0 7,0 62041 68663 1,6 34,0 10,0 7,0 62043 68664 For patent 1,7 34,0 10,0 7,0 62045 68665 information visit www.ksptpatents.com 1,8 36,0 11,0 8,0 62047 68666 1,9 36,0 11,0 8,0 62049 68667 2,0 38,0 12,0 9,0 62051 68668 2,1 38,0 12,0 9,0 62053 68669 2,2 40,0 13,0 10,0 62055 68670 2,3 40,0 13,0 10,0 62057 68671 2,4 43,0 14,0 11,0 62059 68672 2,5 43,0 14,0 11,0 62061 68673 2,6 43,0 14,0 11,0 62063 68674 2,7 46,0 16,0 12,0 62065 68675 2,8 46,0 16,0 12,0 62067 68676 continued on next page www.kyoceraD-sRgILsLtoSol.com DRILLS 293

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов