Общий каталог SGS 2018 - страница 97

Навигация

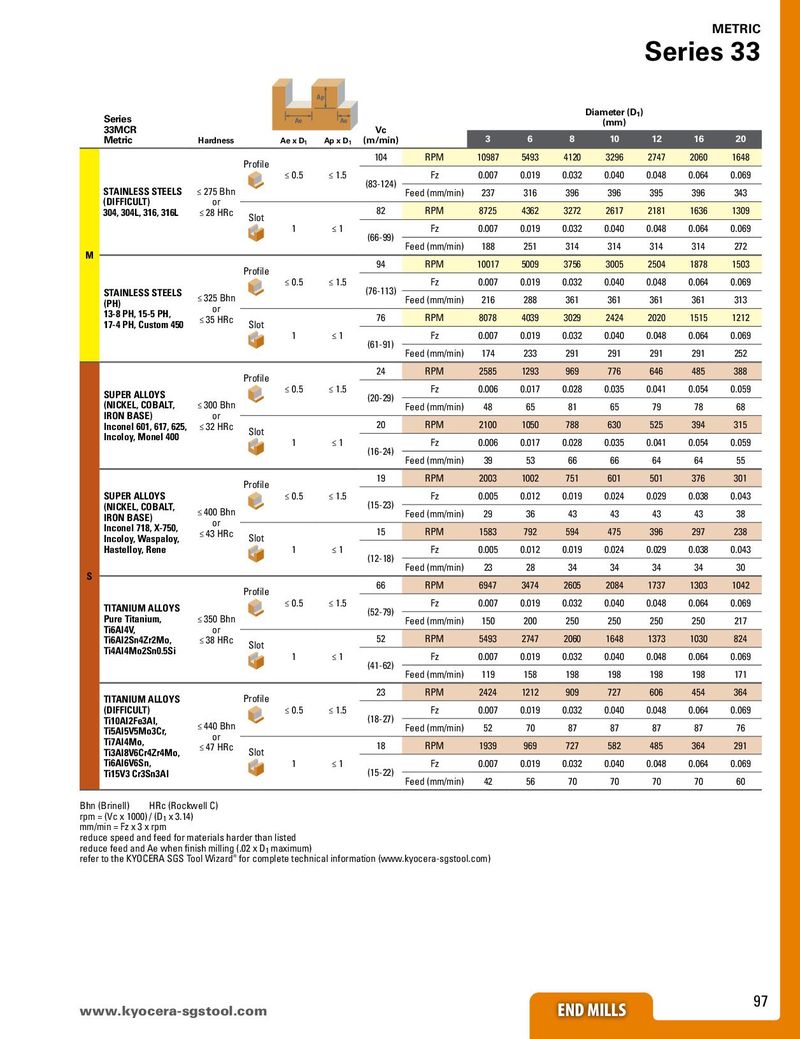

METRIC Series 33 Ap Series Diameter (D1) Ae Ae (mm) 33MCR Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 3 6 8 10 12 16 20 Profile 104 RPM 10987 5493 4120 3296 2747 2060 1648 ≤ 0.5 ≤ 1.5 (83-124) Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 STAINLESS STEELS ≤ 275 Bhn Feed (mm/min) 237 316 396 396 395 396 343 (DIFFICULT) or 82 RPM 8725 4362 3272 2617 2181 1636 1309 304, 304L, 316, 316L ≤ 28 HRc Slot 1 ≤1 (66-99) Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 M Feed (mm/min) 188 251 314 314 314 314 272 Profile 94 RPM 10017 5009 3756 3005 2504 1878 1503 ≤ 0.5 ≤ 1.5 (76-113) Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 STAINLESS STEELS ≤ 325 Bhn Feed (mm/min) 216 288 361 361 361 361 313 (PH) or 13-8 PH, 15-5 PH, ≤ 35 HRc 76 RPM 8078 4039 3029 2424 2020 1515 1212 17-4 PH, Custom 450 Slot 1 ≤1 (61-91) Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 Feed (mm/min) 174 233 291 291 291 291 252 Profile 24 RPM 2585 1293 969 776 646 485 388 SUPER ALLOYS ≤ 0.5 ≤ 1.5 (20-29) Fz 0.006 0.017 0.028 0.035 0.041 0.054 0.059 (NICKEL, COBALT, ≤ 300 Bhn Feed (mm/min) 48 65 81 65 79 78 68 IRON BASE) or 20 RPM 2100 1050 788 630 525 394 315 Inconel 601, 617, 625, ≤ 32 HRc Slot Incoloy, Monel 400 1 ≤1 Fz 0.006 0.017 0.028 0.035 0.041 0.054 0.059 (16-24) Feed (mm/min) 39 53 66 66 64 64 55 Profile 19 RPM 2003 1002 751 601 501 376 301 SUPER ALLOYS ≤ 0.5 ≤ 1.5 (15-23) Fz 0.005 0.012 0.019 0.024 0.029 0.038 0.043 (NICKEL, COBALT, ≤ 400 Bhn Feed (mm/min) 29 36 43 43 43 43 38 IRON BASE) or Inconel 718, X-750, ≤ 43 HRc 15 RPM 1583 792 594 475 396 297 238 Incoloy, Waspaloy, Slot Hastelloy, Rene 1 ≤1 (12-18) Fz 0.005 0.012 0.019 0.024 0.029 0.038 0.043 S Feed (mm/min) 23 28 34 34 34 34 30 Profile 66 RPM 6947 3474 2605 2084 1737 1303 1042 TITANIUM ALLOYS ≤ 0.5 ≤ 1.5 (52-79) Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 Pure Titanium, ≤ 350 Bhn Feed (mm/min) 150 200 250 250 250 250 217 Ti6Al4V, or 52 RPM 5493 2747 2060 1648 1373 1030 824 Ti6Al2Sn4Zr2Mo, ≤ 38 HRc Slot Ti4Al4Mo2Sn0.5Si 1 ≤1 Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 (41-62) Feed (mm/min) 119 158 198 198 198 198 171 TITANIUM ALLOYS Profile 23 RPM 2424 1212 909 727 606 454 364 (DIFFICULT) ≤ 0.5 ≤ 1.5 (18-27) Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 Ti10Al2Fe3Al, ≤ 440 Bhn Feed (mm/min) 52 70 87 87 87 87 76 Ti5Al5V5Mo3Cr, or Ti7Al4Mo, ≤ 47 HRc 18 RPM 1939 969 727 582 485 364 291 Ti3Al8V6Cr4Zr4Mo, Slot Ti6Al6V6Sn, 1 ≤1 (15-22) Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 Ti15V3 Cr3Sn3Al Feed (mm/min) 42 56 70 70 70 70 60 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x 3 x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x D1 maximum) refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 97

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском