Общий каталог SGS 2018 - страница 80

Навигация

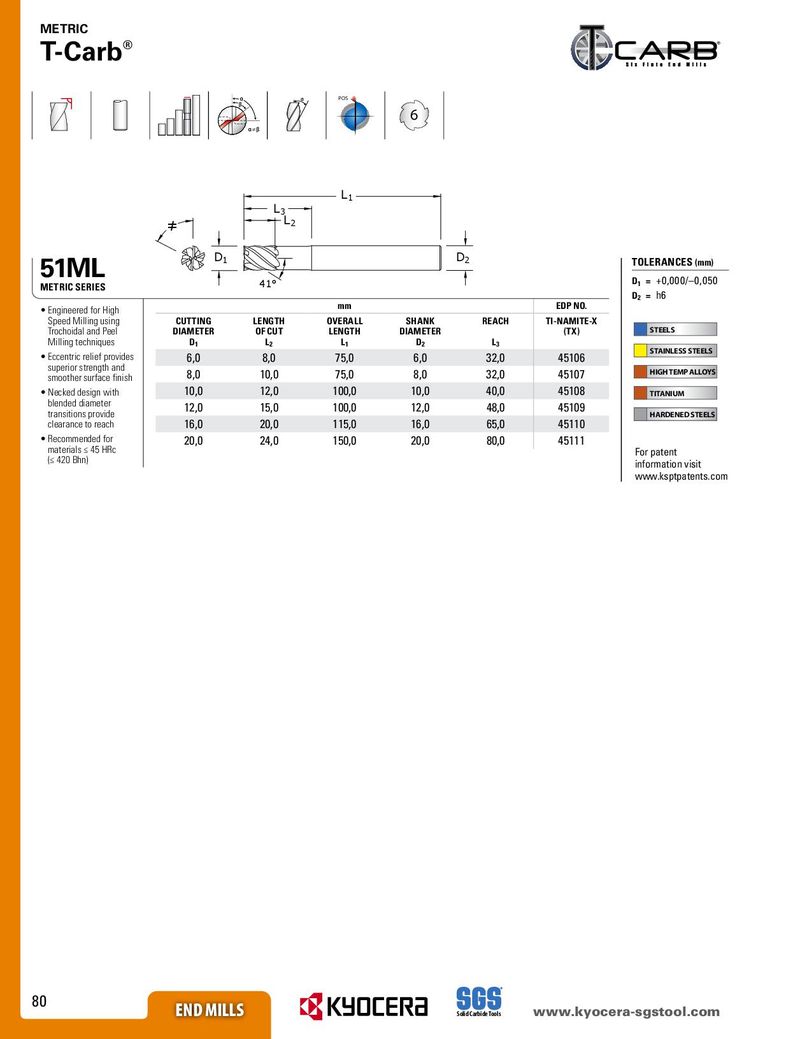

METRIC T-Carb® ® POS 6 ≠ L1 L3 L2 ≠ 51ML D1 D2 TOLERANCES (mm) METRIC SERIES 41° D1 = +0,000/–0,050 D2 = h6 • Engineered for High mm EDP NO. Speed Milling using CUTTING LENGTH OVERALL SHANK REACH TI-NAMITE-X Trochoidal and Peel DIAMETER OF CUT LENGTH DIAMETER (TX) STEELS Milling techniques D1 L2 L1 D2 L3 • Eccentric relief provides 6,0 8,0 75,0 6,0 32,0 45106 STAINLESS STEELS superior strength and 8,0 10,0 75,0 8,0 32,0 45107 HIGH TEMP ALLOYS smoother surface finish • Necked design with 10,0 12,0 100,0 10,0 40,0 45108 TITANIUM blended diameter 12,0 15,0 100,0 12,0 48,0 45109 transitions provide HARDENED STEELS clearance to reach 16,0 20,0 115,0 16,0 65,0 45110 • Recommended for 20,0 24,0 150,0 20,0 80,0 45111 materials ≤ 45 HRc For patent (≤ 420 Bhn) information visit www.ksptpatents.com 80 END MILLS wwwE.kNyDoMceILraLS-sgstool.com Solid Carbide Tools

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском