Общий каталог SGS 2018 - страница 74

Навигация

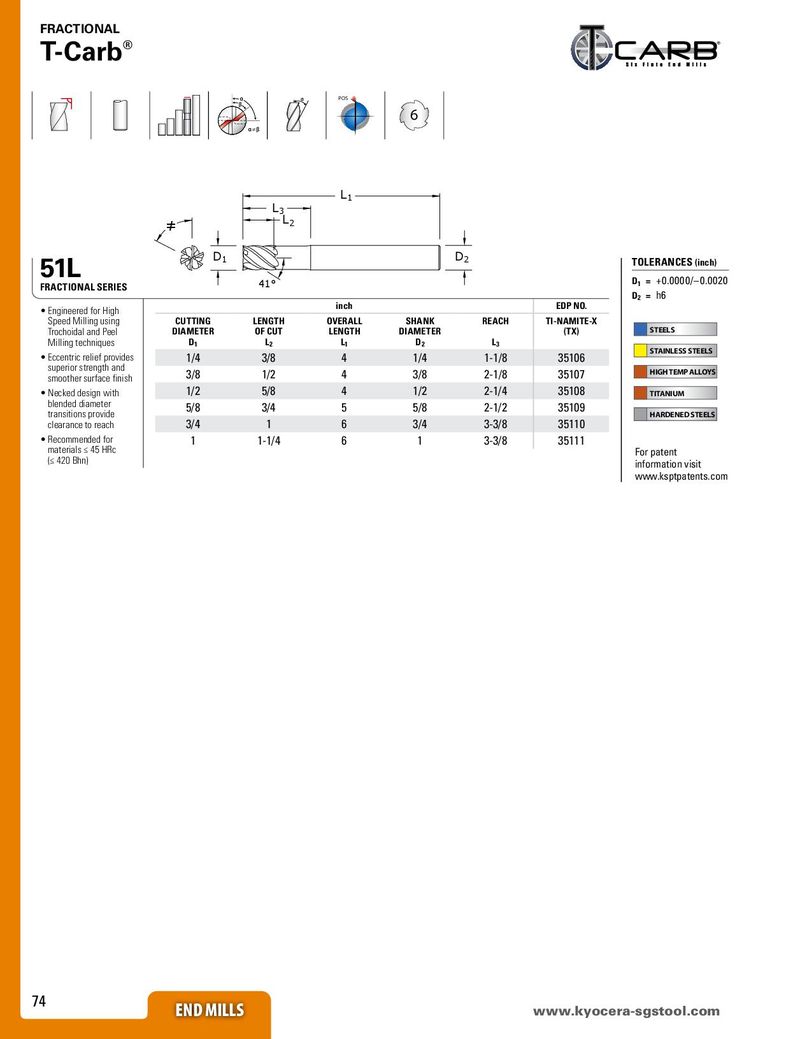

FRACTIONAL T-Carb® ® POS 6 ≠ L1 L3 L2 ≠ 51L D1 D2 TOLERANCES (inch) FRACTIONAL SERIES 41° D1 = +0.0000/–0.0020 D2 = h6 • Engineered for High inch EDP NO. Speed Milling using CUTTING LENGTH OVERALL SHANK REACH TI-NAMITE-X Trochoidal and Peel DIAMETER OF CUT LENGTH DIAMETER (TX) STEELS Milling techniques D1 L2 L1 D2 L3 • Eccentric relief provides 1/4 3/8 4 1/4 1-1/8 35106 STAINLESS STEELS superior strength and 3/8 1/2 4 3/8 2-1/8 35107 HIGH TEMP ALLOYS smoother surface finish • Necked design with 1/2 5/8 4 1/2 2-1/4 35108 TITANIUM blended diameter 5/8 3/4 5 5/8 2-1/2 35109 transitions provide HARDENED STEELS clearance to reach 3/4 1 6 3/4 3-3/8 35110 • Recommended for 1 1-1/4 6 1 3-3/8 35111 materials ≤ 45 HRc For patent (≤ 420 Bhn) information visit www.ksptpatents.com 74 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском