Общий каталог SGS 2018 - страница 70

Навигация

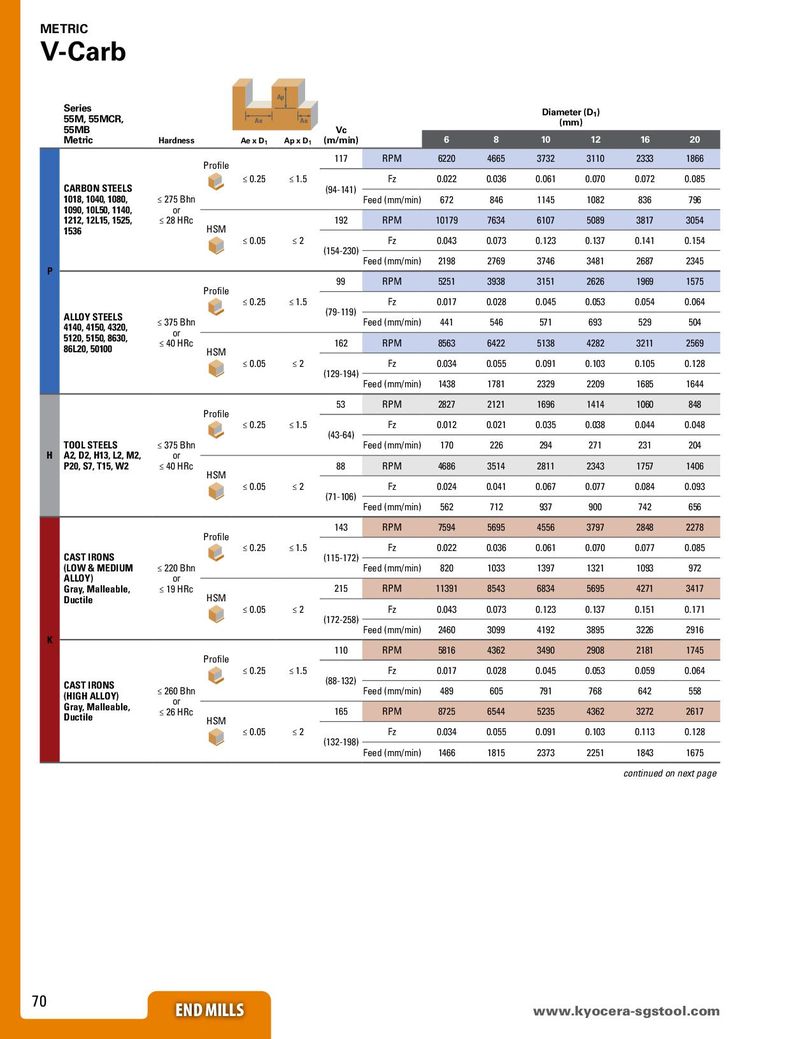

METRIC V-Carb Ap Series Diameter (D1) 55M, 55MCR, Ae Ae (mm) 55MB Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 6 8 10 12 16 20 Profile 117 RPM 6220 4665 3732 3110 2333 1866 ≤ 0.25 ≤ 1.5 Fz 0.022 0.036 0.061 0.070 0.072 0.085 CARBON STEELS (94-141) 1018, 1040, 1080, ≤ 275 Bhn Feed (mm/min) 672 846 1145 1082 836 796 1090, 10L50, 1140, or 1212, 12L15, 1525, ≤ 28 HRc 192 RPM 10179 7634 6107 5089 3817 3054 1536 HSM ≤ 0.05 ≤2 Fz 0.043 0.073 0.123 0.137 0.141 0.154 (154-230) Feed (mm/min) 2198 2769 3746 3481 2687 2345 P 99 RPM 5251 3938 3151 2626 1969 1575 Profile ≤ 0.25 ≤ 1.5 Fz 0.017 0.028 0.045 0.053 0.054 0.064 ALLOY STEELS (79-119) 4140, 4150, 4320, ≤ 375 Bhn Feed (mm/min) 441 546 571 693 529 504 5120, 5150, 8630, or 86L20, 50100 ≤ 40 HRc 162 RPM 8563 6422 5138 4282 3211 2569 HSM ≤ 0.05 ≤2 Fz 0.034 0.055 0.091 0.103 0.105 0.128 (129-194) Feed (mm/min) 1438 1781 2329 2209 1685 1644 53 RPM 2827 2121 1696 1414 1060 848 Profile ≤ 0.25 ≤ 1.5 Fz 0.012 0.021 0.035 0.038 0.044 0.048 (43-64) TOOL STEELS ≤ 375 Bhn Feed (mm/min) 170 226 294 271 231 204 H A2, D2, H13, L2, M2, or P20, S7, T15, W2 ≤ 40 HRc 88 RPM 4686 3514 2811 2343 1757 1406 HSM ≤ 0.05 ≤2 Fz 0.024 0.041 0.067 0.077 0.084 0.093 (71-106) Feed (mm/min) 562 712 937 900 742 656 143 RPM 7594 5695 4556 3797 2848 2278 Profile ≤ 0.25 ≤ 1.5 Fz 0.022 0.036 0.061 0.070 0.077 0.085 CAST IRONS (115-172) (LOW & MEDIUM ≤ 220 Bhn Feed (mm/min) 820 1033 1397 1321 1093 972 ALLOY) or Gray, Malleable, ≤ 19 HRc 215 RPM 11391 8543 6834 5695 4271 3417 Ductile HSM ≤ 0.05 ≤2 Fz 0.043 0.073 0.123 0.137 0.151 0.171 (172-258) Feed (mm/min) 2460 3099 4192 3895 3226 2916 K 110 RPM 5816 4362 3490 2908 2181 1745 Profile ≤ 0.25 ≤ 1.5 Fz 0.017 0.028 0.045 0.053 0.059 0.064 CAST IRONS (88-132) (HIGH ALLOY) ≤ 260 Bhn Feed (mm/min) 489 605 791 768 642 558 Gray, Malleable, or Ductile ≤ 26 HRc 165 RPM 8725 6544 5235 4362 3272 2617 HSM ≤ 0.05 ≤2 Fz 0.034 0.055 0.091 0.103 0.113 0.128 (132-198) Feed (mm/min) 1466 1815 2373 2251 1843 1675 continued on next page 70 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском