Общий каталог SGS 2018 - страница 42

Навигация

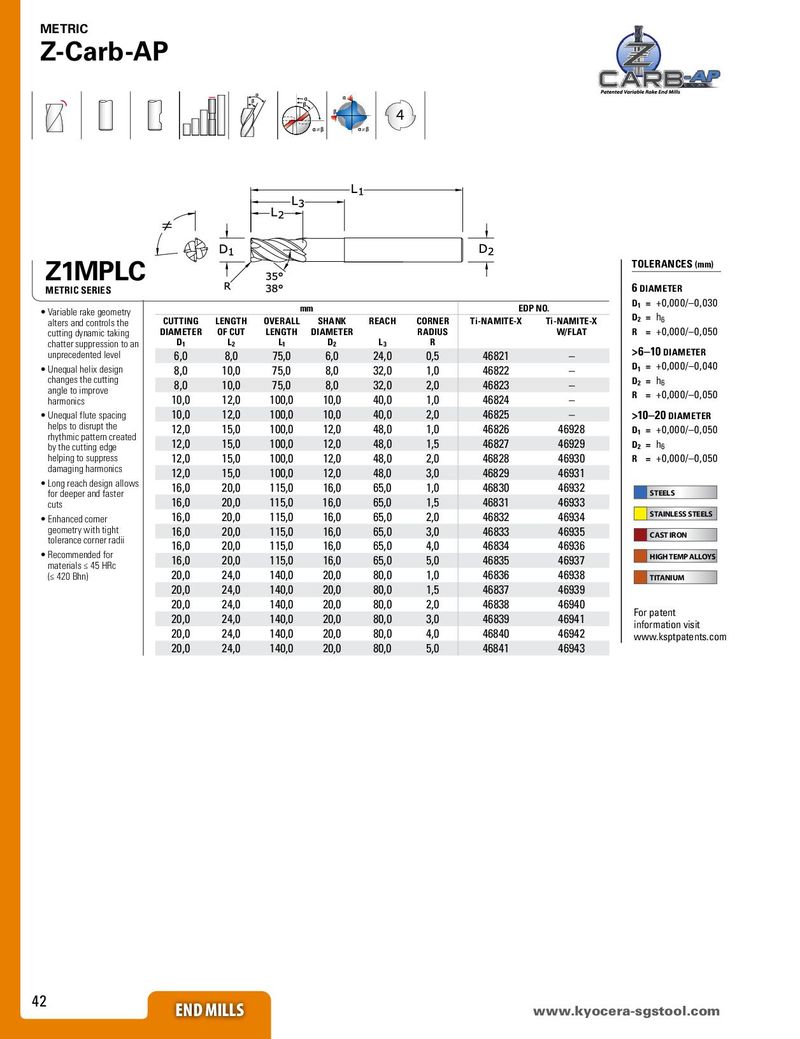

METRIC Z-Carb-AP 4 ≠ ≠ Z1MPLC TOLERANCES (mm) METRIC SERIES 6 DIAMETER • Variable rake geometry mm EDP NO. D1 = +0,000/–0,030 alters and controls the CUTTING LENGTH OVERALL SHANK REACH CORNER Ti-NAMITE-X Ti-NAMITE-X D2 = h6 cutting dynamic taking DIAMETER OF CUT LENGTH DIAMETER RADIUS W/FLAT R = +0,000/–0,050 chatter suppression to an D1 L2 L1 D2 L3 R >6–10 DIAMETER unprecedented level 6,0 8,0 75,0 6,0 24,0 0,5 46821 – • Unequal helix design 8,0 10,0 75,0 8,0 32,0 1,0 46822 – D1 = +0,000/–0,040 changes the cutting 8,0 10,0 75,0 8,0 32,0 2,0 46823 – D2 = h6 angle to improve 10,0 12,0 100,0 10,0 40,0 1,0 46824 – R = +0,000/–0,050 harmonics • Unequal flute spacing 10,0 12,0 100,0 10,0 40,0 2,0 46825 – >10–20 DIAMETER helps to disrupt the 12,0 15,0 100,0 12,0 48,0 1,0 46826 46928 D1 = +0,000/–0,050 rhythmic pattern created 12,0 15,0 100,0 12,0 48,0 1,5 46827 46929 D2 = h6 by the cutting edge helping to suppress 12,0 15,0 100,0 12,0 48,0 2,0 46828 46930 R = +0,000/–0,050 damaging harmonics 12,0 15,0 100,0 12,0 48,0 3,0 46829 46931 • Long reach design allows 16,0 20,0 115,0 16,0 65,0 1,0 46830 46932 for deeper and faster STEELS cuts 16,0 20,0 115,0 16,0 65,0 1,5 46831 46933 • Enhanced corner 16,0 20,0 115,0 16,0 65,0 2,0 46832 46934 STAINLESS STEELS geometry with tight 16,0 20,0 115,0 16,0 65,0 3,0 46833 46935 CAST IRON tolerance corner radii 16,0 20,0 115,0 16,0 65,0 4,0 46834 46936 • Recommended for 16,0 20,0 115,0 16,0 65,0 5,0 46835 46937 HIGH TEMP ALLOYS materials ≤ 45 HRc 20,0 24,0 140,0 20,0 80,0 1,0 46836 46938 (≤ 420 Bhn) TITANIUM 20,0 24,0 140,0 20,0 80,0 1,5 46837 46939 20,0 24,0 140,0 20,0 80,0 2,0 46838 46940 For patent 20,0 24,0 140,0 20,0 80,0 3,0 46839 46941 information visit 20,0 24,0 140,0 20,0 80,0 4,0 46840 46942 www.ksptpatents.com 20,0 24,0 140,0 20,0 80,0 5,0 46841 46943 42 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском