Общий каталог SGS 2018 - страница 227

Навигация

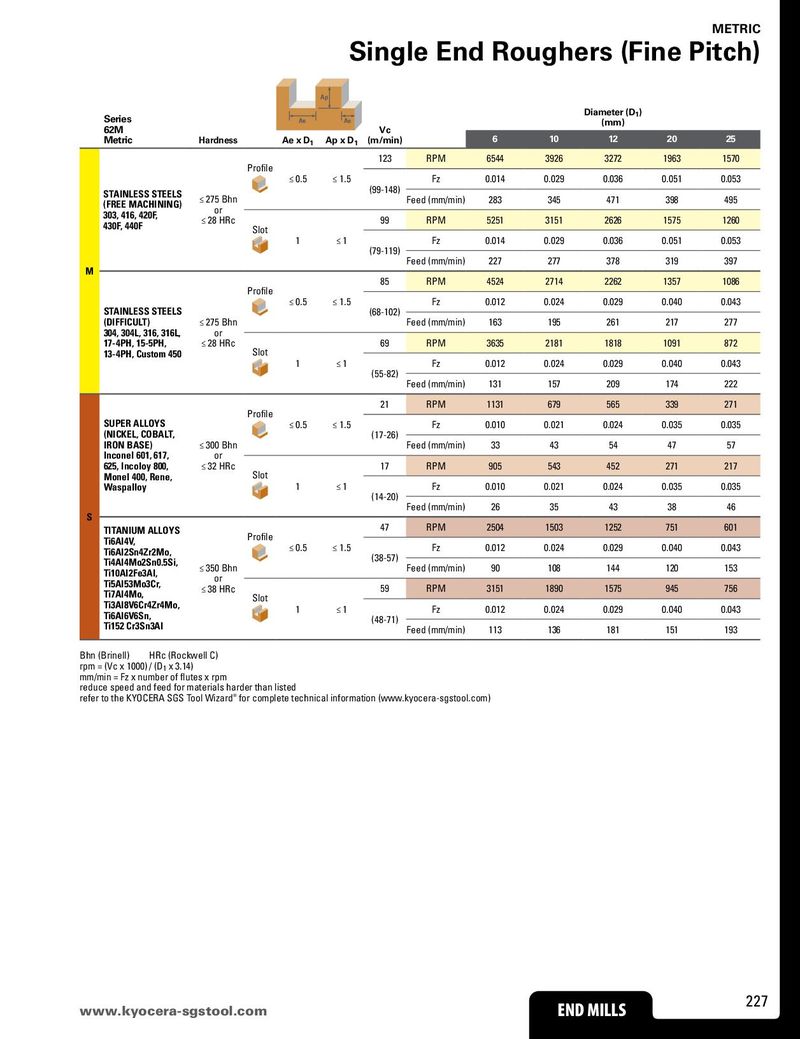

METRIC Single End Roughers (Fine Pitch) Ap Series Diameter (D1) Ae Ae (mm) 62M Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 6 10 12 20 25 123 RPM 6544 3926 3272 1963 1570 Profile ≤ 0.5 ≤ 1.5 Fz 0.014 0.029 0.036 0.051 0.053 STAINLESS STEELS (99-148) (FREE MACHINING) ≤ 275 Bhn Feed (mm/min) 283 345 471 398 495 303, 416, 420F, or 430F, 440F ≤ 28 HRc 99 RPM 5251 3151 2626 1575 1260 Slot 1 ≤1 Fz 0.014 0.029 0.036 0.051 0.053 (79-119) Feed (mm/min) 227 277 378 319 397 M 85 RPM 4524 2714 2262 1357 1086 Profile ≤ 0.5 ≤ 1.5 Fz 0.012 0.024 0.029 0.040 0.043 STAINLESS STEELS (68-102) (DIFFICULT) ≤ 275 Bhn Feed (mm/min) 163 195 261 217 277 304, 304L, 316, 316L, or 17-4PH, 15-5PH, ≤ 28 HRc 69 RPM 3635 2181 1818 1091 872 13-4PH, Custom 450 Slot 1 ≤1 Fz 0.012 0.024 0.029 0.040 0.043 (55-82) Feed (mm/min) 131 157 209 174 222 21 RPM 1131 679 565 339 271 Profile SUPER ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.010 0.021 0.024 0.035 0.035 (NICKEL, COBALT, (17-26) IRON BASE) ≤ 300 Bhn Feed (mm/min) 33 43 54 47 57 Inconel 601, 617, or 625, Incoloy 800, ≤ 32 HRc 17 RPM 905 543 452 271 217 Monel 400, Rene, Slot Waspalloy 1 ≤1 Fz 0.010 0.021 0.024 0.035 0.035 (14-20) Feed (mm/min) 26 35 43 38 46 S TITANIUM ALLOYS 47 RPM 2504 1503 1252 751 601 Ti6Al4V, Profile Ti6Al2Sn4Zr2Mo, ≤ 0.5 ≤ 1.5 Fz 0.012 0.024 0.029 0.040 0.043 Ti4Al4Mo2Sn0.5Si, (38-57) Ti10Al2Fe3Al, ≤ 350 Bhn Feed (mm/min) 90 108 144 120 153 Ti5Al53Mo3Cr, or Ti7Al4Mo, ≤ 38 HRc 59 RPM 3151 1890 1575 945 756 Ti3Al8V6Cr4Zr4Mo, Slot Ti6Al6V6Sn, 1 ≤1 Fz 0.012 0.024 0.029 0.040 0.043 Ti152 Cr3Sn3Al (48-71) Feed (mm/min) 113 136 181 151 193 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x number of flutes x rpm reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 227

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском