Общий каталог SGS 2018 - страница 203

Навигация

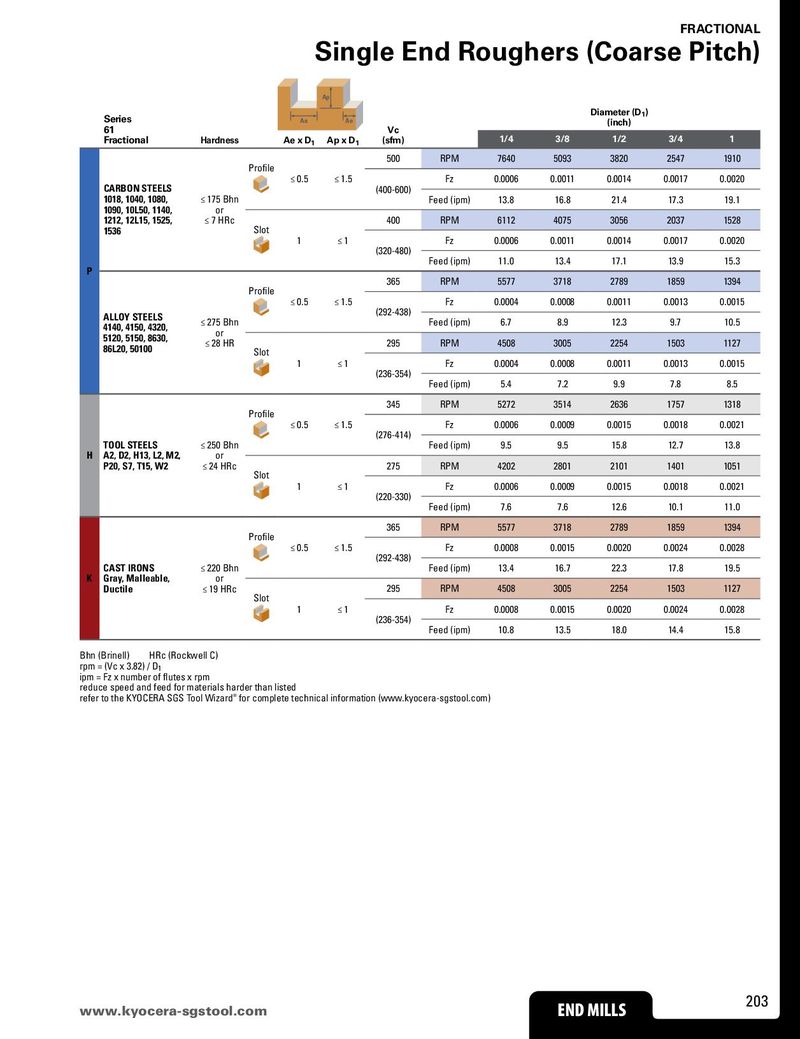

FRACTIONAL Single End Roughers (Coarse Pitch) Ap Series Diameter (D1) Ae Ae (inch) 61 Vc Fractional Hardness Ae x D1 Ap x D1 (sfm) 1/4 3/8 1/2 3/4 1 500 RPM 7640 5093 3820 2547 1910 Profile ≤ 0.5 ≤ 1.5 Fz 0.0006 0.0011 0.0014 0.0017 0.0020 CARBON STEELS (400-600) 1018, 1040, 1080, ≤ 175 Bhn Feed (ipm) 13.8 16.8 21.4 17.3 19.1 1090, 10L50, 1140, or 1212, 12L15, 1525, ≤ 7 HRc 400 RPM 6112 4075 3056 2037 1528 1536 Slot 1 ≤1 Fz 0.0006 0.0011 0.0014 0.0017 0.0020 (320-480) Feed (ipm) 11.0 13.4 17.1 13.9 15.3 P 365 RPM 5577 3718 2789 1859 1394 Profile ≤ 0.5 ≤ 1.5 Fz 0.0004 0.0008 0.0011 0.0013 0.0015 ALLOY STEELS (292-438) 4140, 4150, 4320, ≤ 275 Bhn Feed (ipm) 6.7 8.9 12.3 9.7 10.5 5120, 5150, 8630, or 86L20, 50100 ≤ 28 HR 295 RPM 4508 3005 2254 1503 1127 Slot 1 ≤1 Fz 0.0004 0.0008 0.0011 0.0013 0.0015 (236-354) Feed (ipm) 5.4 7.2 9.9 7.8 8.5 345 RPM 5272 3514 2636 1757 1318 Profile ≤ 0.5 ≤ 1.5 Fz 0.0006 0.0009 0.0015 0.0018 0.0021 (276-414) TOOL STEELS ≤ 250 Bhn Feed (ipm) 9.5 9.5 15.8 12.7 13.8 H A2, D2, H13, L2, M2, or P20, S7, T15, W2 ≤ 24 HRc 275 RPM 4202 2801 2101 1401 1051 Slot 1 ≤1 Fz 0.0006 0.0009 0.0015 0.0018 0.0021 (220-330) Feed (ipm) 7.6 7.6 12.6 10.1 11.0 365 RPM 5577 3718 2789 1859 1394 Profile ≤ 0.5 ≤ 1.5 Fz 0.0008 0.0015 0.0020 0.0024 0.0028 (292-438) CAST IRONS ≤ 220 Bhn Feed (ipm) 13.4 16.7 22.3 17.8 19.5 K Gray, Malleable, or Ductile ≤ 19 HRc 295 RPM 4508 3005 2254 1503 1127 Slot 1 ≤1 Fz 0.0008 0.0015 0.0020 0.0024 0.0028 (236-354) Feed (ipm) 10.8 13.5 18.0 14.4 15.8 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 3.82) / D1 ipm = Fz x number of flutes x rpm reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 203

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском