Общий каталог SGS 2018 - страница 20

Навигация

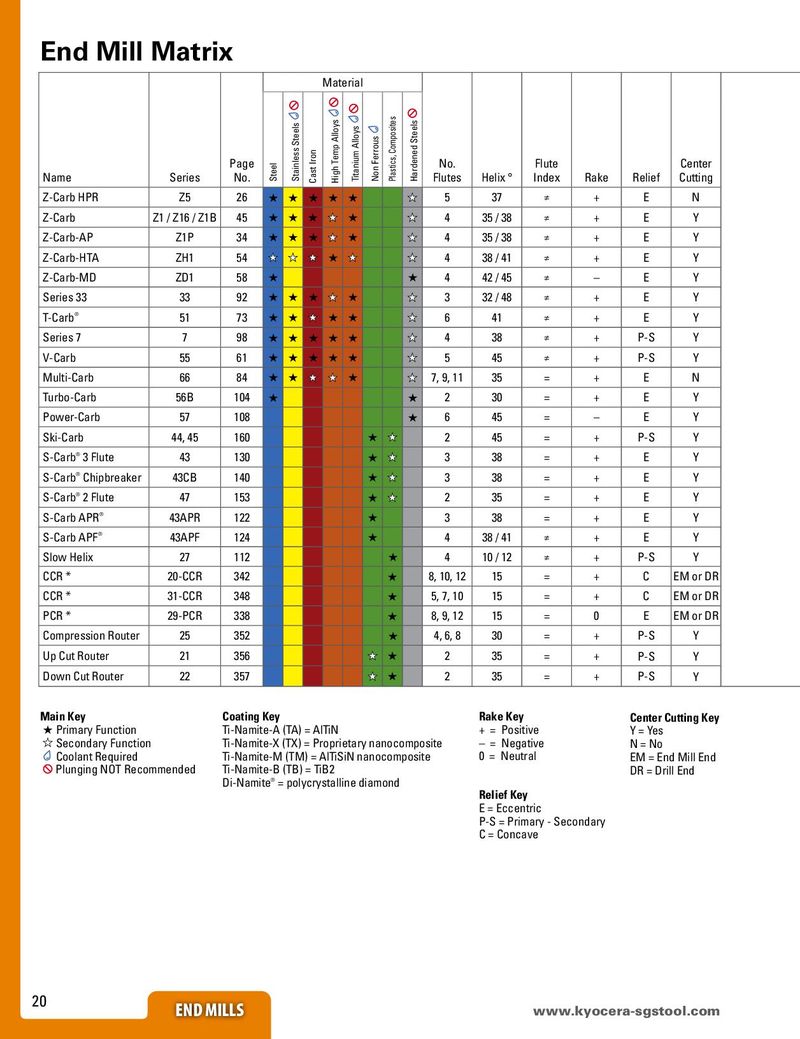

End Mill Matrix Material Page Steel Stainless Steels Cast Iron High Temp Alloys Titanium Alloys Non Ferrous Plastics, Composites Hardened Steels No. Flute Center Name Series No. Flutes Helix ° Index Rake Relief Cutting Z-Carb HPR Z5 26 ★ ★ ★ ★ ★ 5 37 ≠ + E N Z-Carb Z1 / Z16 / Z1B 45 ★ ★ ★ ★ 4 35 / 38 ≠ + E Y Z-Carb-AP Z1P 34 ★ ★ ★ ★ 4 35 / 38 ≠ + E Y Z-Carb-HTA ZH1 54 ★ 4 38 / 41 ≠ + E Y Z-Carb-MD ZD1 58 ★ ★ 4 42 / 45 ≠ – E Y Series 33 33 92 ★ ★ ★ ★ 3 32 / 48 ≠ + E Y T-Carb® 51 73 ★ ★ ★ ★ 6 41 ≠ + E Y Series 7 7 98 ★ ★ ★ ★ ★ 4 38 ≠ + P-S Y V-Carb 55 61 ★ ★ ★ ★ ★ 5 45 ≠ + P-S Y Multi-Carb 66 84 ★ ★ ★ 7, 9, 11 35 = + E N Turbo-Carb 56B 104 ★ ★ 2 30 = + E Y Power-Carb 57 108 ★ 6 45 = – E Y Ski-Carb 44, 45 160 ★ 2 45 = + P-S Y S-Carb® 3 Flute 43 130 ★ 3 38 = + E Y S-Carb® Chipbreaker 43CB 140 ★ 3 38 = + E Y S-Carb® 2 Flute 47 153 ★ 2 35 = + E Y S-Carb APR® 43APR 122 ★ 3 38 = + E Y S-Carb APF® 43APF 124 ★ 4 38 / 41 ≠ + E Y Slow Helix 27 112 ★ 4 10 / 12 ≠ + P-S Y CCR * 20-CCR 342 ★ 8, 10, 12 15 = + C EM or DR CCR * 31-CCR 348 ★ 5, 7, 10 15 = + C EM or DR PCR * 29-PCR 338 ★ 8, 9, 12 15 = 0 E EM or DR Compression Router 25 352 ★ 4, 6, 8 30 = + P-S Y Up Cut Router 21 356 ★ 2 35 = + P-S Y Down Cut Router 22 357 ★ 2 35 = + P-S Y Main Key Coating Key Rake Key Center Cutting Key ★ Primary Function Ti-Namite-A (TA) = AlTiN + = Positive Y = Yes Secondary Function Ti-Namite-X (TX) = Proprietary nanocomposite – = Negative N = No Coolant Required Ti-Namite-M (TM) = AlTiSiN nanocomposite 0 = Neutral EM = End Mill End Plunging NOT Recommended Ti-Namite-B (TB) = TiB2 DR = Drill End Di-Namite® = polycrystalline diamond Relief Key E = Eccentric P-S = Primary - Secondary C = Concave 20 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском