Общий каталог SGS 2018 - страница 155

Навигация

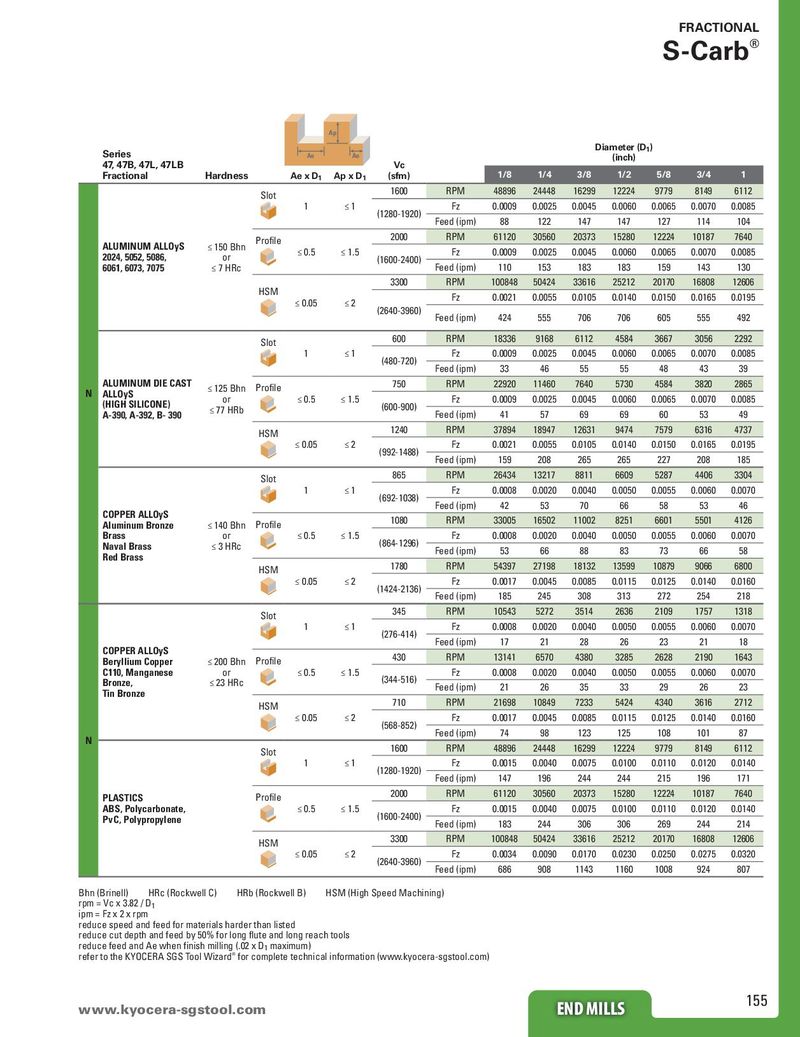

FRACTIONAL S-Carb® Ap Series Diameter (D1) Ae Ae (inch) 47, 47B, 47L, 47LB Vc Fractional Hardness Ae x D1 Ap x D1 (sfm) 1/8 1/4 3/8 1/2 5/8 3/4 1 Slot 1600 RPM 48896 24448 16299 12224 9779 8149 6112 1 ≤1 (1280-1920) Fz 0.0009 0.0025 0.0045 0.0060 0.0065 0.0070 0.0085 Feed (ipm) 88 122 147 147 127 114 104 Profile 2000 RPM 61120 30560 20373 15280 12224 10187 7640 Aluminum AlloyS ≤ 150 Bhn ≤ 0.5 ≤ 1.5 Fz 0.0009 0.0025 0.0045 0.0060 0.0065 0.0070 0.0085 2024, 5052, 5086, or (1600-2400) 6061, 6073, 7075 ≤ 7 HRc Feed (ipm) 110 153 183 183 159 143 130 3300 RPM 100848 50424 33616 25212 20170 16808 12606 HSM Fz 0.0021 0.0055 0.0105 0.0140 0.0150 0.0165 0.0195 ≤ 0.05 ≤2 (2640-3960) Feed (ipm) 424 555 706 706 605 555 492 Slot 600 RPM 18336 9168 6112 4584 3667 3056 2292 1 ≤1 (480-720) Fz 0.0009 0.0025 0.0045 0.0060 0.0065 0.0070 0.0085 Feed (ipm) 33 46 55 55 48 43 39 Aluminum Die Cast ≤ 125 Bhn Profile 750 RPM 22920 11460 7640 5730 4584 3820 2865 N AlloyS or ≤ 0.5 ≤ 1.5 Fz 0.0009 0.0025 0.0045 0.0060 0.0065 0.0070 0.0085 (High Silicone) ≤ 77 HRb (600-900) A-390, A-392, B- 390 Feed (ipm) 41 57 69 69 60 53 49 HSM 1240 RPM 37894 18947 12631 9474 7579 6316 4737 ≤ 0.05 ≤2 (992-1488) Fz 0.0021 0.0055 0.0105 0.0140 0.0150 0.0165 0.0195 Feed (ipm) 159 208 265 265 227 208 185 Slot 865 RPM 26434 13217 8811 6609 5287 4406 3304 1 ≤1 (692-1038) Fz 0.0008 0.0020 0.0040 0.0050 0.0055 0.0060 0.0070 Copper AlloyS Feed (ipm) 42 53 70 66 58 53 46 Aluminum Bronze ≤ 140 Bhn Profile 1080 RPM 33005 16502 11002 8251 6601 5501 4126 Brass or ≤ 0.5 ≤ 1.5 (864-1296) Fz 0.0008 0.0020 0.0040 0.0050 0.0055 0.0060 0.0070 Naval Brass ≤ 3 HRc Feed (ipm) 53 66 88 83 73 66 58 Red Brass 1780 RPM 54397 27198 18132 13599 10879 9066 6800 HSM ≤ 0.05 ≤2 (1424-2136) Fz 0.0017 0.0045 0.0085 0.0115 0.0125 0.0140 0.0160 Feed (ipm) 185 245 308 313 272 254 218 Slot 345 RPM 10543 5272 3514 2636 2109 1757 1318 1 ≤1 (276-414) Fz 0.0008 0.0020 0.0040 0.0050 0.0055 0.0060 0.0070 Copper AlloyS Feed (ipm) 17 21 28 26 23 21 18 Beryllium Copper ≤ 200 Bhn Profile 430 RPM 13141 6570 4380 3285 2628 2190 1643 C110, Manganese or ≤ 0.5 ≤ 1.5 (344-516) Fz 0.0008 0.0020 0.0040 0.0050 0.0055 0.0060 0.0070 Bronze, ≤ 23 HRc Feed (ipm) 21 26 35 33 29 26 23 Tin Bronze 710 RPM 21698 10849 7233 5424 4340 3616 2712 HSM ≤ 0.05 ≤2 (568-852) Fz 0.0017 0.0045 0.0085 0.0115 0.0125 0.0140 0.0160 N Feed (ipm) 74 98 123 125 108 101 87 Slot 1600 RPM 48896 24448 16299 12224 9779 8149 6112 1 ≤1 (1280-1920) Fz 0.0015 0.0040 0.0075 0.0100 0.0110 0.0120 0.0140 Feed (ipm) 147 196 244 244 215 196 171 PLASTICS Profile 2000 RPM 61120 30560 20373 15280 12224 10187 7640 ABS, Polycarbonate, ≤ 0.5 ≤ 1.5 (1600-2400) Fz 0.0015 0.0040 0.0075 0.0100 0.0110 0.0120 0.0140 PV C, Polypropylene Feed (ipm) 183 244 306 306 269 244 214 HSM 3300 RPM 100848 50424 33616 25212 20170 16808 12606 ≤ 0.05 ≤2 (2640-3960) Fz 0.0034 0.0090 0.0170 0.0230 0.0250 0.0275 0.0320 Feed (ipm) 686 908 1143 1160 1008 924 807 Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) HSM (High Speed Machining) rpm = Vc x 3.82 / D1 ipm = Fz x 2 x rpm reduce speed and feed for materials harder than listed reduce cut depth and feed by 50% for long flute and long reach tools reduce feed and Ae when finish milling (.02 x D1 maximum) refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 155

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском