Общий каталог SGS 2018 - страница 154

Навигация

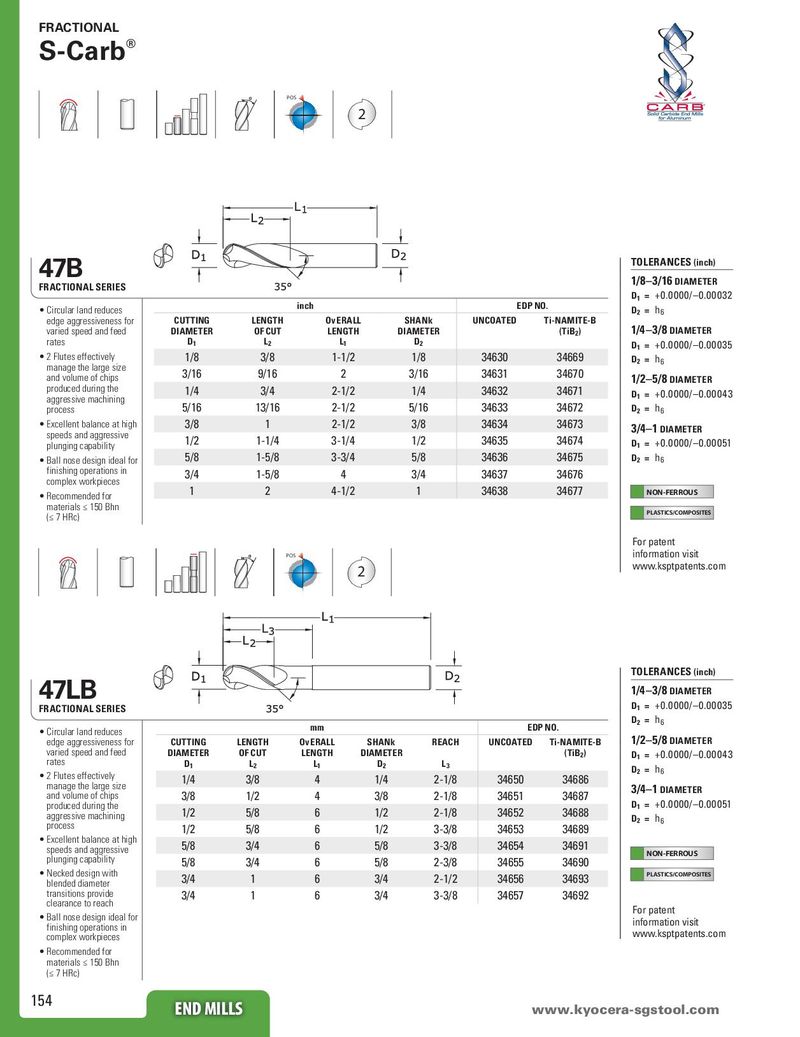

FRACTIONAL S-Carb® POS 2 ® 47B TOLERANCES (inch) Fractional Series 1/8–3/16 DIAMETER D1 = +0.0000/–0.00032 • Circular land reduces inch EDP No. D2 = h6 edge aggressiveness for Cutting Length Ov erall Shank Uncoated Ti-NAMITE-B 1/4–3/8 DIAMETER varied speed and feed Diameter of Cut Length Diameter (TiB2) rates D1 l2 L1 D2 D1 = +0.0000/–0.00035 • 2 Flutes effectively 1/8 3/8 1-1/2 1/8 34630 34669 D2 = h6 manage the large size 3/16 9/16 2 3/16 34631 34670 and volume of chips 1/2–5/8 DIAMETER produced during the 1/4 3/4 2-1/2 1/4 34632 34671 D1 = +0.0000/–0.00043 aggressive machining 5/16 13/16 2-1/2 5/16 34633 34672 h6 process D2 = • Excellent balance at high 3/8 1 2-1/2 3/8 34634 34673 3/4–1 DIAMETER speeds and aggressive 1/2 1-1/4 3-1/4 1/2 34635 34674 D1 = +0.0000/–0.00051 plunging capability • Ball nose design ideal for 5/8 1-5/8 3-3/4 5/8 34636 34675 D2 = h6 finishing operations in 3/4 1-5/8 4 3/4 34637 34676 complex workpieces 1 2 4-1/2 1 34638 34677 • Recommended for NON-FERROUS materials ≤ 150 Bhn PLASTICS/COMPOSITES (≤ 7 HRc) For patent POS information visit 2 www.ksptpatents.com TOLERANCES (inch) 47LB 1/4–3/8 DIAMETER FRACTIONAL Series D1 = +0.0000/–0.00035 mm EDP No. D2 = h6 • Circular land reduces 1/2–5/8 DIAMETER edge aggressiveness for Cutting Length Ov erall Shank Reach UNCoated Ti-NAMITE-B varied speed and feed Diameter of Cut Length DiaMETER (TiB2) D1 = +0.0000/–0.00043 rates D1 l2 L1 D2 L3 D2 = h6 • 2 Flutes effectively 1/4 3/8 4 1/4 2-1/8 34650 34686 manage the large size 3/4–1 DIAMETER and volume of chips 3/8 1/2 4 3/8 2-1/8 34651 34687 D1 = +0.0000/–0.00051 produced during the 1/2 5/8 6 1/2 2-1/8 34652 34688 aggressive machining D2 = h6 process 1/2 5/8 6 1/2 3-3/8 34653 34689 • Excellent balance at high 5/8 3/4 6 5/8 3-3/8 34654 34691 speeds and aggressive NON-FERROUS plunging capability 5/8 3/4 6 5/8 2-3/8 34655 34690 • Necked design with 3/4 1 6 3/4 2-1/2 34656 34693 PLASTICS/COMPOSITES blended diameter transitions provide 3/4 1 6 3/4 3-3/8 34657 34692 clearance to reach For patent • Ball nose design ideal for information visit finishing operations in www.ksptpatents.com complex workpieces • Recommended for materials ≤ 150 Bhn (≤ 7 HRc) 154 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском