Общий каталог SGS 2018 - страница 13

Навигация

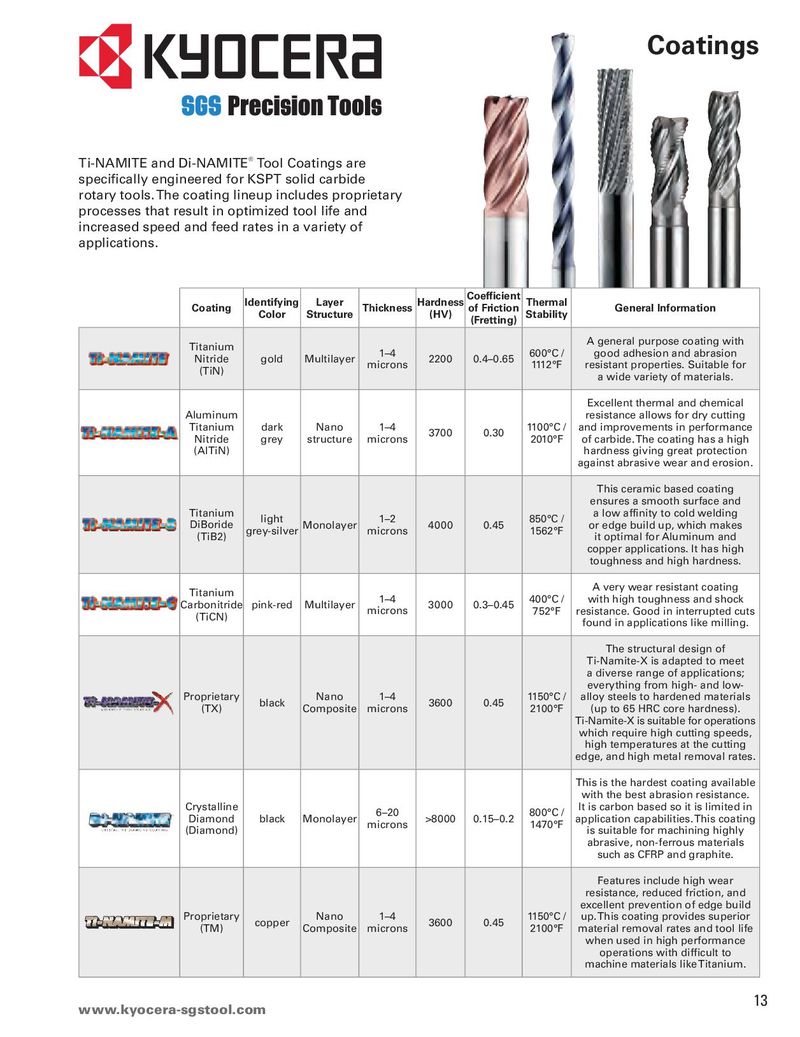

Coatings Ti-NAMITE and Di-NAMITE® Tool Coatings are specifically engineered for KSPT solid carbide rotary tools. The coating lineup includes proprietary processes that result in optimized tool life and increased speed and feed rates in a variety of applications. MORE THAN JUST ANOTHER CUTTING TOOL SUPPLIER PRCEoCaItSinIgONIdTeOCnoOtilfoLyriSngEUStRLruaOyctePurEre, Thickness HKaY(rHdOVnCe) sEsRCo(AoFf reFefSrftiitcGcitniieSognn)tPSTrehtaecbrimisliitaoyl n General Information KYOCERA SGS LTD. Tools Europe also offers The state of the art KYOCERA SGS Precision a full range of end mill andAdgreinllerparlopdurupcotsse caosatfiongllowwiths: ifsacfoilTciNtiut(yaTistnriieNiisdud)emloocnatthegdeolmidnaWnoMukfuailntcilgtauyhreaermom,f i1c–ro4ns Tools Europe • Mo22fu0C0ltai-tMal0oi.l4gli–o0P.n6r5oEduur61co01t10Ws2°C°Fa/rehroegusaiosswoteadindSatedtpvohraoecrspkieieiotnryntgieoasfnF.mduSaalulbtietRraraibasalinleosg.nfoer England and special cutting tools, high accuracy form tools, • Same Day Shipment on Stock Items tool modi cations and regrinds. A highly skilled • Multi-Lingual Sales and TeEcxhcenlliecnatlthSeurmpaploarntd chemical team of professioATnluitamalnsiinusumpmeciadliazrek in theNasnuopply • OI3n7nf0ol0irnmeaPtoi0or.3nta0 al nfodr1212S00410t0-o°H°CcFok/ uAarvonrOfaedcsirailimdsartbbeapindrriloceiPvet.yTelaamh,lclePoeewcrnmoitscsaifetinoinnnrggptd,ehrrDyafosicsruamctthoaininuggchnet 1–4 and support of higNhitrpideerformagrnecye tosotlrsucftourrethemicrons Aerospace, Medica(Al,lTPiNo)wer Generation and • High Performance ProduachgatairandsnntedasbsArgapisvpivinleigcwagetraeioratnapnTrdroaeteriocntsiiionongn., Motorsport markets. Including the New KYOCERA SGS Tool Clinic This ceramic based coating Titanium light 1–2 A• AR4d0edF0si0atpisootnnTsraael0c.s4Cke5efronvritcrSee81ps5506ep°2cCr°iFoa/ vl TidoecoeoadirnltpslesooapudVpwetrgtrieietaamsahfbpfaOaiiupnslsilufilimtodfcyraarouttcRAooipoilta,luhcniwpmtossyl.ihudidInirticwufnhhameaccmlesldauahiannkdnidgegedsh: DiBoride grey-silver Monolayer microns (TiB2) • Product Research and Devtoeuloghpnmesesnatnd high hardness. • Product Engineering and Tool Application Support • C30A0D0 /CA0M.3–0S.4o5ftw4a70r50e2°°CSF/uprepswoiAsirttthvaenhrciyeg.whGetooaour dgrehisnniesintsastneartrncudopastethidnogcckuts Titanium 1–4 Carbonitride pink-red Multilayer microns (TiCN) found in applications like milling. The structural design of Ti-Namite-X is adapted to meet a diverse range of applications; everything from high- and low- Proprietary black Nano 1–4 3600 0.45 1150°C / alloy steels to hardened materials (TX) Composite microns 2100°F (up to 65 HRC core hardness). Ti-Namite-X is suitable for operations which require high cutting speeds, high temperatures at the cutting edge, and high metal removal rates. This is the hardest coating available with the best abrasion resistance. Crystalline 6–20 800°C / It is carbon based so it is limited in Diamond black Monolayer microns >8000 0.15–0.2 1470°F application capabilities. This coating (Diamond) is suitable for machining highly abrasive, non-ferrous materials such as CFRP and graphite. Features include high wear resistance, reduced friction, and excellent prevention of edge build Proprietary copper Nano 1–4 3600 0.45 1150°C / up. This coating provides superior (TM) Composite microns 2100°F material removal rates and tool life when used in high performance operations with difficult to machine materials like Titanium. www.kyocera-sgstool.com 13

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском