Общий каталог SGS 2018 - страница 129

Навигация

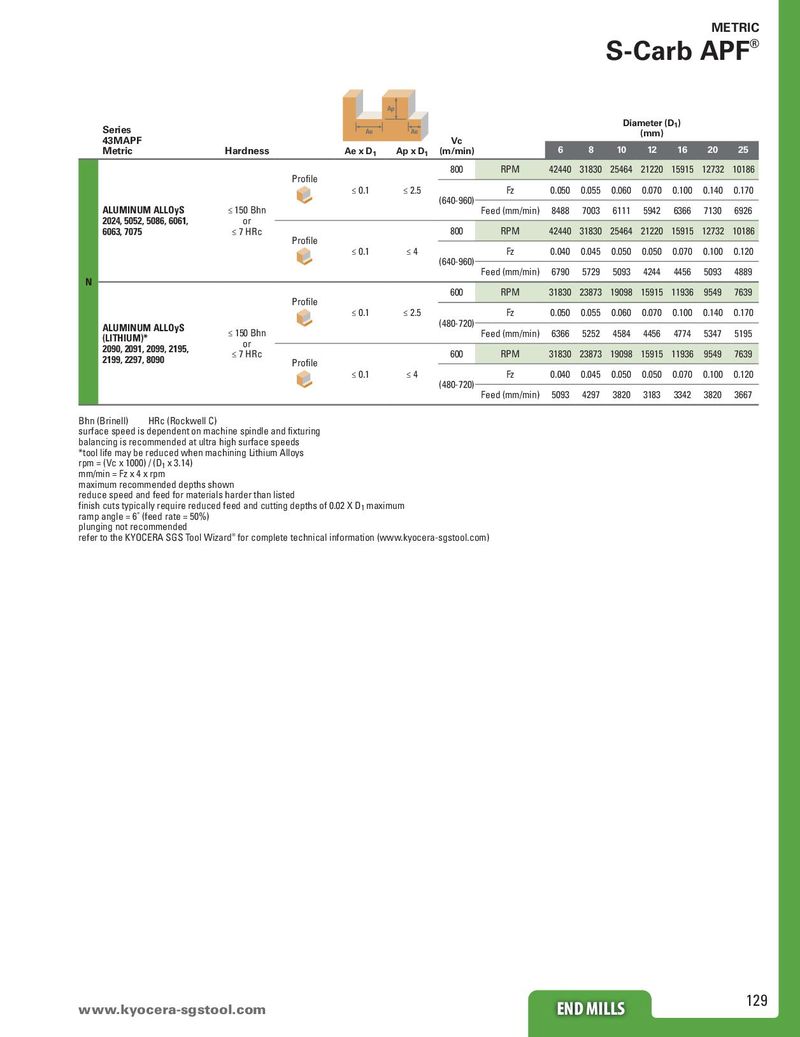

METRIC S-Carb APF® Ap Series Diameter (D1) Ae Ae (mm) 43MAPF Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 6 8 10 12 16 20 25 800 RPM 42440 31830 25464 21220 15915 12732 10186 Profile ≤ 0.1 ≤ 2.5 Fz 0.050 0.055 0.060 0.070 0.100 0.140 0.170 (640-960) Aluminum AlloyS ≤ 150 Bhn Feed (mm/min) 8488 7003 6111 5942 6366 7130 6926 2024, 5052, 5086, 6061, or 6063, 7075 ≤ 7 HRc 800 RPM 42440 31830 25464 21220 15915 12732 10186 Profile ≤ 0.1 ≤4 Fz 0.040 0.045 0.050 0.050 0.070 0.100 0.120 (640-960) Feed (mm/min) 6790 5729 5093 4244 4456 5093 4889 N 600 RPM 31830 23873 19098 15915 11936 9549 7639 Profile ≤ 0.1 ≤ 2.5 Fz 0.050 0.055 0.060 0.070 0.100 0.140 0.170 Aluminum AlloyS (480-720) (LITHIUM)* ≤ 150 Bhn Feed (mm/min) 6366 5252 4584 4456 4774 5347 5195 2090, 2091, 2099, 2195, or 2199, 2297, 8090 ≤ 7 HRc 600 RPM 31830 23873 19098 15915 11936 9549 7639 Profile ≤ 0.1 ≤4 Fz 0.040 0.045 0.050 0.050 0.070 0.100 0.120 (480-720) Feed (mm/min) 5093 4297 3820 3183 3342 3820 3667 Bhn (Brinell) HRc (Rockwell C) surface speed is dependent on machine spindle and fixturing balancing is recommended at ultra high surface speeds *tool life may be reduced when machining Lithium Alloys rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x 4 x rpm maximum recommended depths shown reduce speed and feed for materials harder than listed finish cuts typically require reduced feed and cutting depths of 0.02 X D1 maximum ramp angle = 6˚ (feed rate = 50%) plunging not recommended refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 129

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском