Каталог SGS микро инструмент 2021 - страница 72

Навигация

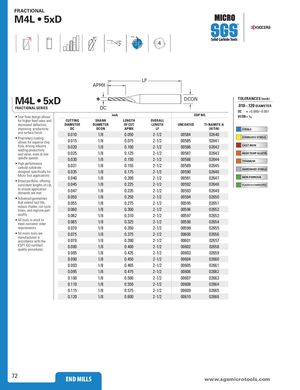

FRACTIONAL M4L • 5xD 30° POS 15° 4 LF APMX M4L • 5xD DCON TOLERANCES (inch) FRACTIONAL SERIES DC .010–.120 DIAMETER DC = +0.000/–0.001 • Four flute design allows inch EDP NO. DCON = h6 for higher feed rates and CUTTING SHANK LENGTH OVERALL decreased deflection, DIAMETER DIAMETER OF CUT LENGTH UNCOATED TI-NAMITE-A improving productivity DC DCON APMX LF (AlTiN) STEELS and surface finish. 0.010 1/8 0.050 2-1/2 00584 02640 • Proprietary coatingallows for superior chip0.015 1/8 0.075 2-1/2 00585 02641 STAINLESS STEELS flow, driving industry 0.020 1/8 0.100 2-1/2 00586 02642 CAST IRON leading productivity and value, even at low 0.025 1/8 0.125 2-1/2 00587 02643 HIGH TEMP ALLOYS spindle speeds. 0.030 1/8 0.150 2-1/2 00588 02644• High performancecarbide substrate0.0311/80.1552-1/20058902645designed specifically for0.0351/80.1752-1/20059002646TITANIUMHARDENED STEELS Micro Tool applications. 0.040 1/8 0.200 2-1/2 00591 02647 NON-FERROUS • Broad portfolio, offering consistent lengths of cut, 0.045 1/8 0.225 2-1/2 00592 02648 PLASTICS/COMPOSITES to ensure applicationdemands are met.0.047 1/8 0.235 2-1/2 00593 02649 • Advanced geometries 0.050 1/8 0.250 2-1/2 00594 02650 that extend tool life, 0.055 1/8 0.275 2-1/2 00595 02651 reduce chatter, cut cycletimes, and improve part0.060 1/8 0.300 2-1/2 00596 02652 quality. 0.062 1/8 0.310 2-1/2 00597 02653 • All tools in stock tomeet customer order0.065 1/8 0.325 2-1/2 00598 02654 requirements. 0.070 1/8 0.350 2-1/2 00599 02655 • All micro tools are 0.075 1/8 0.375 2-1/2 00600 02656 manufactured in accordance with the 0.078 1/8 0.390 2-1/2 00601 02657 KSPT ISO certifiedquality procedures.0.080 1/8 0.400 2-1/2 00602 02658 0.085 1/8 0.425 2-1/2 00603 02659 0.090 1/8 0.450 2-1/2 00604 02660 0.093 1/8 0.465 2-1/2 00605 02661 0.095 1/8 0.475 2-1/2 00606 02662 0.100 1/8 0.500 2-1/2 00607 02663 0.110 1/8 0.550 2-1/2 00608 02664 0.115 1/8 0.575 2-1/2 00609 02665 0.120 1/8 0.600 2-1/2 00610 02666 72 END MILLS wwEwN.DsgMsImLLicSrotools.com

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33