Каталог SGS инструмент для сверления - страница 4

Навигация

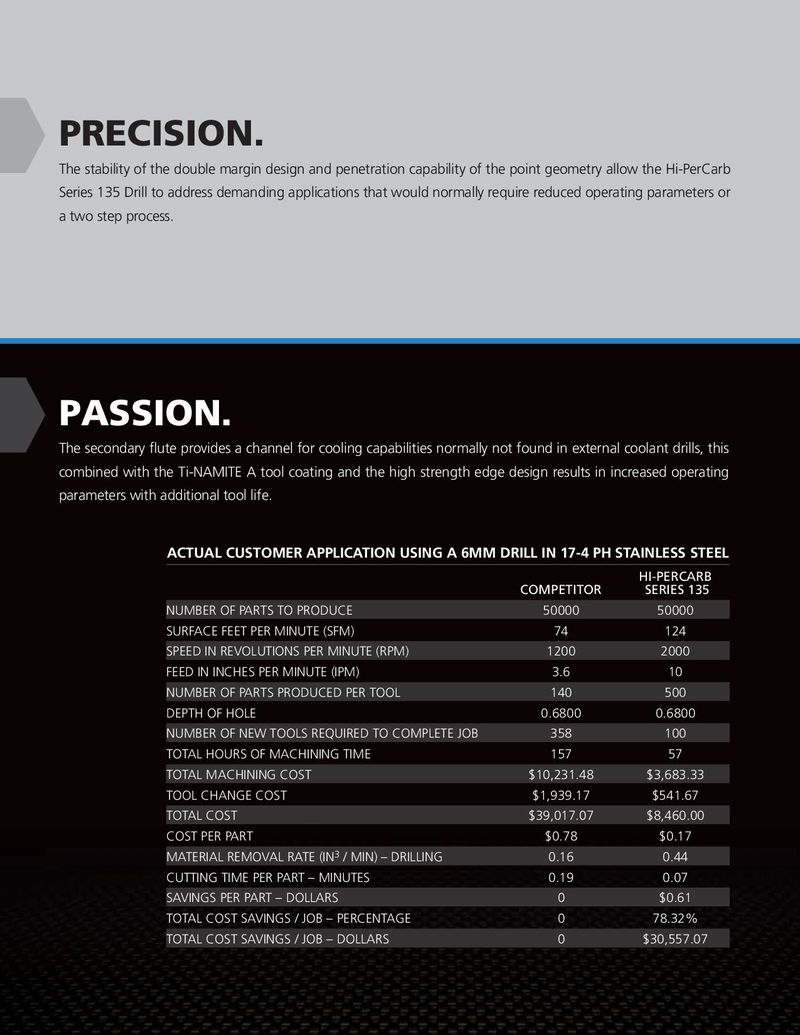

PRECISION. The stability of the double margin design and penetration capability of the point geometry allow the Hi-PerCarb Series 135 Drill to address demanding applications that would normally require reduced operating parameters or a two step process. PASSION. The secondary flute provides a channel for cooling capabilities normally not found in external coolant drills, this combined with the Ti-NAMITE A tool coating and the high strength edge design results in increased operating parameters with additional tool life. ACTUAL CUSTOMER APPLICATION USING A 6MM DRILL IN 17-4 PH STAINLESS STEEL HI-PERCARB COMPETITOR SERIES 135 NUMBER OF PARTS TO PRODUCE 50000 50000 SURFACE FEET PER MINUTE (SFM) 74 124 SPEED IN REVOLUTIONS PER MINUTE (RPM) 1200 2000 FEED IN INCHES PER MINUTE (IPM) 3.6 10 NUMBER OF PARTS PRODUCED PER TOOL 140 500 DEPTH OF HOLE 0.6800 0.6800 NUMBER OF NEW TOOLS REQUIRED TO COMPLETE JOB 358 100 TOTAL HOURS OF MACHINING TIME 157 57 TOTAL MACHINING COST $10,231.48 $3,683.33 TOOL CHANGE COST $1,939.17 $541.67 TOTAL COST $39,017.07 $8,460.00 COST PER PART $0.78 $0.17 MATERIAL REMOVAL RATE (IN3 / MIN) – DRILLING 0.16 0.44 CUTTING TIME PER PART – MINUTES 0.19 0.07 SAVINGS PER PART – DOLLARS 0 $0.61 TOTAL COST SAVINGS / JOB – PERCENTAGE 0 78.32% TOTAL COST SAVINGS / JOB – DOLLARS 0 $30,557.07

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb

Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb Каталог SGS микроинструмент

Каталог SGS микроинструмент Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb