Каталог SGS инструмент для сверления - страница 36

Навигация

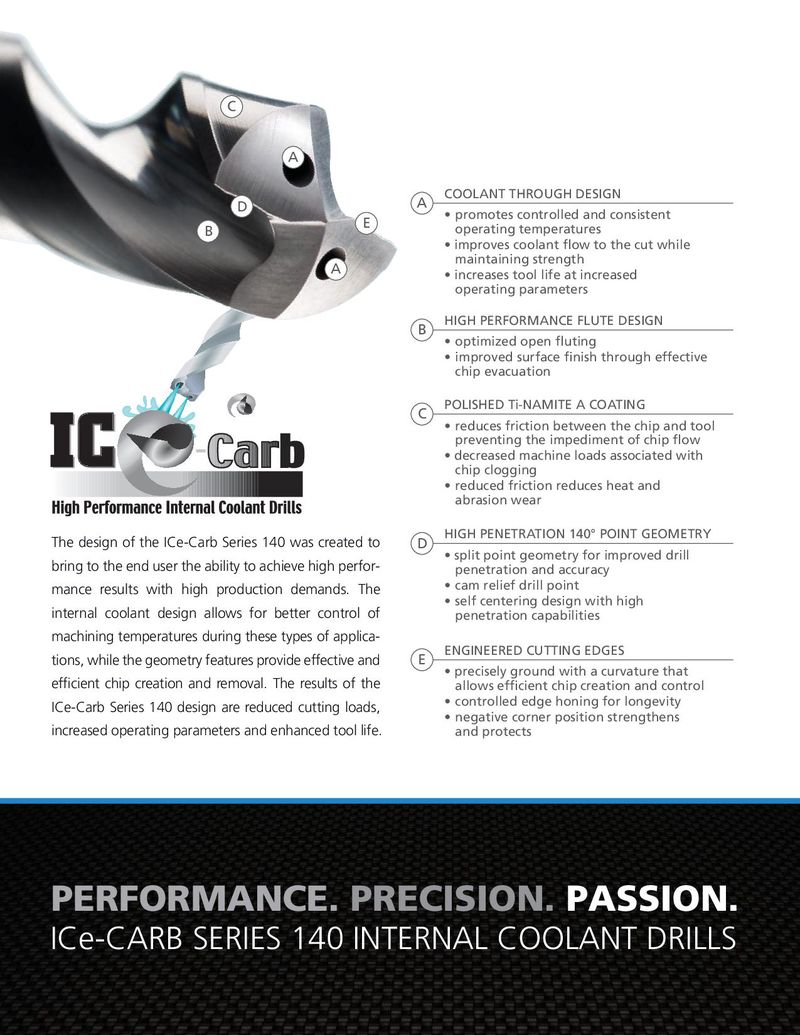

C A A COOLANT THROUGH DESIGN D • promotes controlled and consistent B E operating temperatures • improves coolant flow to the cut while A maintaining strength • increases tool life at increased operating parameters B HIGH PERFORMANCE FLUTE DESIGN • optimized open fluting • improved surface finish through effective chip evacuation C POLISHED Ti-NAMITE A COATING • reduces friction between the chip and tool preventing the impediment of chip flow • decreased machine loads associated with chip clogging • reduced friction reduces heat and abrasion wear The design of the ICe-Carb Series 140 was created to D HIGH PENETRATION 140° POINT GEOMETRY bring to the end user the ability to achieve high perfor- • split point geometry for improved drill penetration and accuracy mance results with high production demands. The • cam relief drill point internal coolant design allows for better control of • self centering design with high penetration capabilities machining temperatures during these types of applica- tions, while the geometry features provide effective and E ENGINEERED CUTTING EDGES efficient chip creation and removal. The results of the • precisely ground with a curvature that allows efficient chip creation and control ICe-Carb Series 140 design are reduced cutting loads, • controlled edge honing for longevity • negative corner position strengthens increased operating parameters and enhanced tool life. and protects PERFORMANCE. PRECISION. PASSION. ICe-CARB SERIES 140 INTERNAL COOLANT DRILLS 36 www.kyocera-sgstool.com

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb

Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb Каталог SGS микроинструмент

Каталог SGS микроинструмент Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb