Каталог SGS инструмент для сверления - страница 35

Навигация

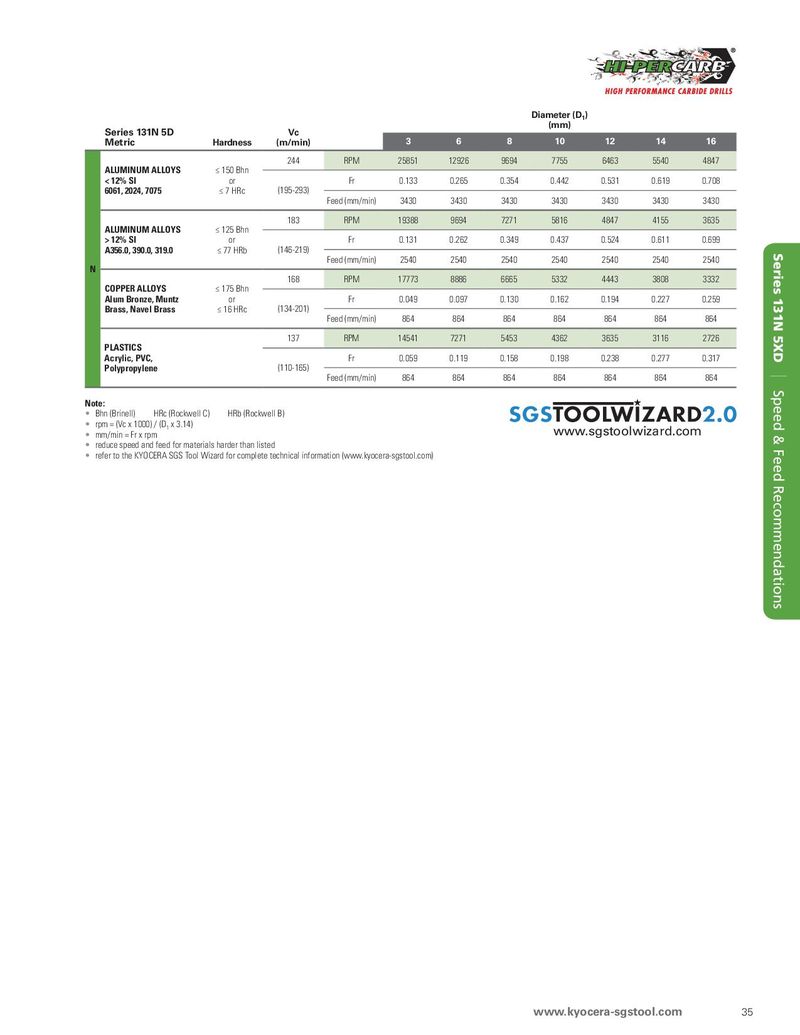

Diameter (D1) Series 131N 5D Vc (mm) Metric Hardness (m/min) 3 6 8 10 12 14 16 244 RPM 25851 12926 9694 7755 6463 5540 4847 ALUMINUM ALLOYS ≤ 150 Bhn < 12% SI or Fr 0.133 0.265 0.354 0.442 0.531 0.619 0.708 6061, 2024, 7075 ≤ 7 HRc (195-293) Feed (mm/min) 3430 3430 3430 3430 3430 3430 3430 183 RPM 19388 9694 7271 5816 4847 4155 3635 ALUMINUM ALLOYS ≤ 125 Bhn > 12% SI or Fr 0.131 0.262 0.349 0.437 0.524 0.611 0.699 A356.0, 390.0, 319.0 ≤ 77 HRb (146-219) Series 131N 5XD Feed (mm/min) 2540 2540 2540 2540 2540 2540 2540 N 168 RPM 17773 8886 6665 5332 4443 3808 3332 COPPER ALLOYS ≤ 175 Bhn Alum Bronze, Muntz or Fr 0.049 0.097 0.130 0.162 0.194 0.227 0.259 Brass, Navel Brass ≤ 16 HRc (134-201) Feed (mm/min) 864 864 864 864 864 864 864 137 RPM 14541 7271 5453 4362 3635 3116 2726 PLASTICS Acrylic, PVC, Fr 0.059 0.119 0.158 0.198 0.238 0.277 0.317 Polypropylene (110-165) Feed (mm/min) 864 864 864 864 864 864 864 | Note: Speed & Feed Recommendations • Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) • rpm = (Vc x 1000) / (D1 x 3.14) www.sgstoolwizard.com • mm/min = Fr x rpm • reduce speed and feed for materials harder than listed • refer to the KYOCERA SGS Tool Wizard for complete technical information (www.kyocera-sgstool.com) www.kyocera-sgstool.com 35

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb

Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb Каталог SGS микроинструмент

Каталог SGS микроинструмент Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb