Каталог SGS инструмент для обработки алюминия - страница 52

Навигация

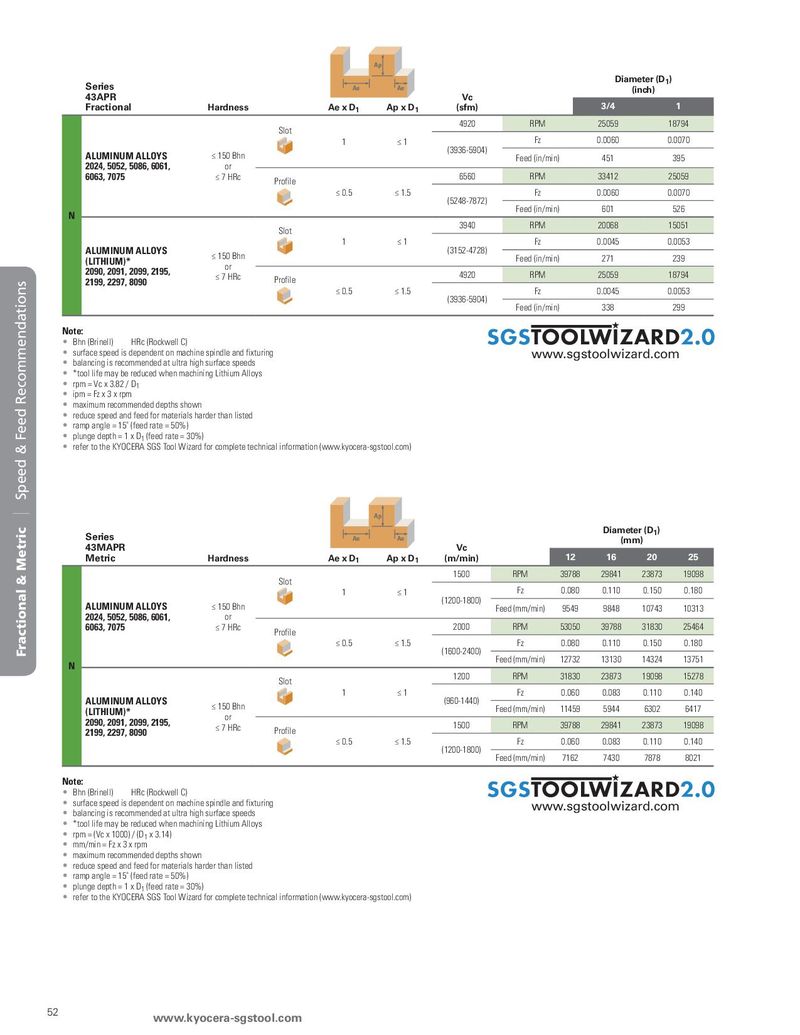

Ap Series Ae Ae Diameter (D1) 43APR Vc (inch) Fractional Hardness Ae x D1 Ap x D1 (sfm) 3/4 1 Slot 4920 RPM 25059 18794 1 ≤1 Fz 0.0060 0.0070 ALUMINUM ALLOYS ≤ 150 Bhn (3936-5904) Feed (in/min) 451 395 2024, 5052, 5086, 6061, or 6063, 7075 ≤ 7 HRc Profile 6560 RPM 33412 25059 ≤ 0.5 ≤ 1.5 (5248-7872) Fz 0.0060 0.0070 N Feed (in/min) 601 526 Slot 3940 RPM 20068 15051 1 ≤1 (3152-4728) Fz 0.0045 0.0053 ALUMINUM ALLOYS ≤ 150 Bhn Feed (in/min) 271 239 (LITHIUM)* or 2090, 2091, 2099, 2195, ≤ 7 HRc Profile 4920 RPM 25059 18794 Speed & Feed Recommendations 2199, 2297, 8090 ≤ 0.5 ≤ 1.5 (3936-5904) Fz 0.0045 0.0053 Feed (in/min) 338 299 Note: • Bhn (Brinell) HRc (Rockwell C) • surface speed is dependent on machine spindle and fixturing www.sgstoolwizard.com • balancing is recommended at ultra high surface speeds • *tool life may be reduced when machining Lithium Alloys • rpm = Vc x 3.82 / D1 • ipm = Fz x 3 x rpm • maximum recommended depths shown • reduce speed and feed for materials harder than listed • ramp angle = 15˚ (feed rate = 50%) • plunge depth = 1 x D1 (feed rate = 30%) • refer to the KYOCERA SGS Tool Wizard for complete technical information (www.kyocera-sgstool.com) | Ap Fractional & Metric Series Ae Ae Diameter (D1) 43MAPR Vc (mm) Metric Hardness Ae x D1 Ap x D1 (m/min) 12 16 20 25 Slot 1500 RPM 39788 29841 23873 19098 1 ≤1 Fz 0.080 0.110 0.150 0.180 ALUMINUM ALLOYS ≤ 150 Bhn (1200-1800) Feed (mm/min) 9549 9848 10743 10313 2024, 5052, 5086, 6061, or 6063, 7075 ≤ 7 HRc Profile 2000 RPM 53050 39788 31830 25464 ≤ 0.5 ≤ 1.5 (1600-2400) Fz 0.080 0.110 0.150 0.180 N Feed (mm/min) 12732 13130 14324 13751 Slot 1200 RPM 31830 23873 19098 15278 1 ≤1 (960-1440) Fz 0.060 0.083 0.110 0.140 ALUMINUM ALLOYS ≤ 150 Bhn Feed (mm/min) 11459 5944 6302 6417 (LITHIUM)* or 2090, 2091, 2099, 2195, ≤ 7 HRc Profile 1500 RPM 39788 29841 23873 19098 2199, 2297, 8090 ≤ 0.5 ≤ 1.5 (1200-1800) Fz 0.060 0.083 0.110 0.140 Feed (mm/min) 7162 7430 7878 8021 Note: • Bhn (Brinell) HRc (Rockwell C) • surface speed is dependent on machine spindle and fixturing www.sgstoolwizard.com • balancing is recommended at ultra high surface speeds • *tool life may be reduced when machining Lithium Alloys • rpm = (Vc x 1000) / (D1 x 3.14) • mm/min = Fz x 3 x rpm • maximum recommended depths shown • reduce speed and feed for materials harder than listed • ramp angle = 15˚ (feed rate = 50%) • plunge depth = 1 x D1 (feed rate = 30%) • refer to the KYOCERA SGS Tool Wizard for complete technical information (www.kyocera-sgstool.com) 52 www.kyocera-sgstool.com

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы с переменным углом спирали Z-carb

Каталог SGS фрезы с переменным углом спирали Z-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb