Общий каталог PRECITOOL - страница 14

Навигация

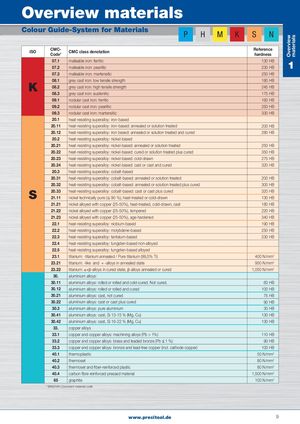

BOmvoatehrrevriiweaelrswkzeuge Overview materials Colour Guide-System for Materials P H M K S N ISO CMC-Code1CMC class denotation Referencehardness 07.1 malleable iron: ferritic07.2malleable iron: pearlitic 130 HB230 HB1 07.3 malleable iron: martensitic 250 HB 08.1 grey cast iron: low tensile strength 180 HB K 08.2 grey cast iron: high tensile strength 245 HB 08.3 grey cast iron: austenitic 175 HB 09.1 nodular cast iron: ferritic 160 HB 09.2 nodular cast iron: pearlitic 250 HB 09.3 nodular cast iron: martensitic 330 HB 20.1 heat-resisting superalloy: iron-based 20.11 heat-resisting superalloy: iron-based: annealed or solution treated 200 HB 20.12 heat-resisting superalloy: iron based: annealed or solution treated and cured 280 HB 20.2 heat-resisting superalloy: nickel-based 20.21 heat-resisting superalloy: nickel-based: annealed or solution treated 250 HB 20.22 heat-resisting superalloy: nickel-based: cured or solution treated plus cured 350 HB 20.23 heat-resisting superalloy: nickel-based: cold-drawn 275 HB 20.24 heat-resisting superalloy: nickel-based: cast or cast and cured 320 HB 20.3 heat-resisting superalloy: cobalt-based 20.31 heat-resisting superalloy: cobalt-based: annealed or solution treated 200 HB 20.32 heat-resisting superalloy: cobalt-based: annealed or solution treated plus cured 300 HB S 20.33 heat-resisting superalloy: cobalt-based: cast or cast plus cured21.11nickel technically pure ( 90 %), heat-treated or cold-drawn320 HB130 HB 21.21 nickel alloyed with copper (25-50%), heat-treated, cold-drawn, cast 180 HB 21.22 nickel alloyed with copper (25-50%), tempered 220 HB 21.23 nickel alloyed with copper (25-50%), age-hardened 340 HB 22.1 heat-resisting superalloy: niobium-based 190 HB 22.2 heat-resisting superalloy: molybdene-based 250 HB 22.3 heat-resisting superalloy: tantalum-based 230 HB 22.4 heat-resisting superalloy: tungsten-based non-alloyed 22.5 heat-resisting superalloy: tungsten-based alloyed 23.1 titanium: -titanium annealed / Pure titanium (99,5% Ti) 400 N/mm2 23.21 titanium: -like and + -alloys in annealed state 950 N/mm2 23.22 titanium: +-alloys in cured state, -alloys annealed or cured 1,050 N/mm2 30. aluminium alloys: 30.11 aluminium alloys: rolled or rolled and cold-cured. Not cured. 60 HB 30.12 aluminium alloys: rolled or rolled and cured 100 HB 30.21 aluminium alloys: cast, not cured 75 HB 30.22 aluminium alloys: cast or cast plus cured 90 HB 30.3 aluminium alloys: pure aluminium 30 HB 30.41 aluminium alloys: cast, Si 13-15 % (Mg, Cu) 130 HB 30.42 aluminium alloys: cast, Si 16-22 % (Mg, Cu) 130 HB 33. copper alloys 33.1 copper and copper alloys: machining alloys (Pb > 1%) 110 HB 33.2 copper and copper alloys: brass and leaded bronze (Pb ≤ 1 %) 90 HB 33.3 copper and copper alloys: bronze and lead-free copper (incl. cathode copper) 100 HB 40.1 thermoplastic 50 N/mm2 40.2 thermoset 80 N/mm2 40.3 thermoset and fiber-reinforced plastic 80 N/mm2 40.4 carbon fibre reinforced pressed material 1,500 N/mm2 65 graphite 100 N/mm2 1 SANDVIK-Coromant material code www.precitool.de 9