Общий каталог PRECITOOL - страница 13

Навигация

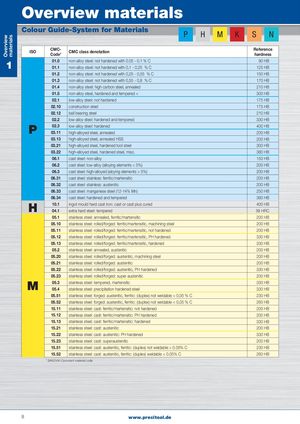

Overview materials Overview materials Colour Guide-System for Materials P H M K S N ISO CMC-Code1CMC class denotation Referencehardness 1 01.0 non-alloy steel: not hardened with 0.05 - 0.1 % C01.1non-alloy steel: not hardened with 0,1 - 0,25%C 90 HB125 HB 01.2 non-alloy steel: not hardened with 0,25 - 0,55 %C 150 HB 01.3 non-alloy steel: not hardened with 0,55 - 0,8 %C 170 HB 01.4 non-alloy steel: high carbon steel, annealed 210 HB 01.5 non-alloy steel, hardened and tempered < 300 HB 02.1 low-alloy steel: not hardened 175 HB 02.10 construction steel 175 HB 02.12 ball bearing steel 210 HB 02.2 low-alloy steel: hardened and tempered 330 HB P 02.3 low-alloy steel: hardened03.11high-alloyed steel, annealed 400 HB200 HB 03.13 high-alloyed steel, annealed HSS 200 HB 03.21 high-alloyed steel, hardened tool steel 300 HB 03.22 high-alloyed steel, hardened steel, misc. 380 HB 06.1 cast steel: non-alloy 150 HB 06.2 cast steel: low-alloy (alloying elements < 5%) 200 HB 06.3 cast steel: high-alloyed (aloying elements > 5%) 200 HB 06.31 cast steel: stainless: ferritic/martensitic 200 HB 06.32 cast steel: stainless: austenitic 200 HB 06.33 cast steel: manganese steel (12-14% Mn) 250 HB 06.34 cast steel: hardened and tempered 380 HB H 10.1 ingot mould hard cast iron: cast or cast plus cured04.1extra hard steel: tempered 400 HB59 HRC 05.1 stainless steel: annealed, ferritic/martensitic 200 HB 05.10 stainless steel: rolled/forged: ferritic/martensitic, machining steel 200 HB 05.11 stainless steel: rolled/forged: ferritic/martensitic, not hardened 200 HB 05.12 stainless steel: rolled/forged: ferritic/martensitic, PH hardened 330 HB 05.13 stainless steel: rolled/forged: ferritic/martensitic, hardened 330 HB 05.2 stainless steel: annealed, austenitic 200 HB 05.20 stainless steel: rolled/forged: austenitic, machining steel 200 HB 05.21 stainless steel: rolled/forged: austenitic 200 HB 05.22 stainless steel: rolled/forged: austenitic, PH hardened 330 HB 05.23 stainless steel: rolled/forged: super austenitic 200 HB M 05.3 stainless steel: tempered, martensitic05.4stainless steel: precipitation hardened steel 330 HB330 HB 05.51 stainless steel: forged: austenitic, ferritic: (duplex) not weldable > 0,05 % C 230 HB 05.52 stainless steel: forged: austenitic, ferritic: (duplex) not weldable < 0,05 % C 260 HB 15.11 stainless steel: cast: ferritic/martensitic: not hardened 200 HB 15.12 stainless steel: cast: ferritic/martensitic: PH hardened 330 HB 15.13 stainless steel: cast: ferritic/martensitic: hardened 330 HB 15.21 stainless steel: cast: austenitic 200 HB 15.22 stainless steel: cast: austenitic: PH hardened 330 HB 15.23 stainless steel: cast: superaustenitic 200 HB 15.51 stainless steel: cast: austenitic, ferritic: (duplex) not weldable > 0.05% C 230 HB 15.52 stainless steel: cast: austenitic, ferritic: (duplex) weldable < 0.05% C 260 HB 1 SANDVIK-Coromant material code 8 www.precitool.de