Общий каталог Osawa 2021 - страница 434

Навигация

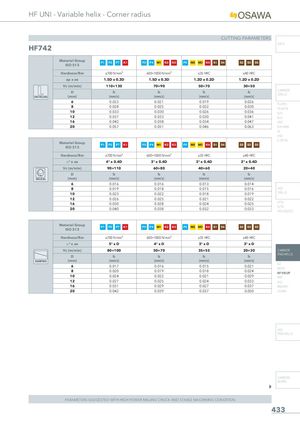

HF UNI - Variable helix - Corner radius CUTTING PARAMETERS INFO HF742 Material GroupISO 513 P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5 Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC ap x ae 1.5D x 0.3D 1.5D x 0.3D 1.2D x 0.2D 1.2D x 0.2D Vc (m/min) 110÷130 70÷90 50÷70 30÷50 D fzSIDE MILLING(mm)(mm/z) fz(mm/z) fz(mm/z) fz(mm/z) CARBIDEDRILLS 6 0.023 0.021 0.019 0.026 PU-HPU 8 0.028 0.025 0.022 0.030 TA-4HTA 10 0.033 0.030 0.026 0.036 SUH 12 0.037 0.033 0.030 0.041 ALH 16 0.042 0.038 0.034 0.047 HRC 20 0.057 0.051 0.046 0.063 SUH MINI HL HSD C-SD-TA Material GroupISO 513 P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5 Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC ° x ae 4° x 0.4D 3° x 0.4D 3° x 0.4D 2° x 0.4D Vc (m/min) 90÷110 60÷80 40÷60 20÷40 D fz fz fz fz HELICAL (mm) (mm/z) (mm/z) (mm/z) (mm/z) 6 0.016 0.016 0.013 0.014 8 0.019 0.018 0.015 0.016 HSS 10 0.023 0.022 0.018 0.019 DRILLS 12 0.026 0.025 0.021 0.022 16 0.030 0.028 0.024 0.025 LFTA 20 0.040 0.038 0.032 0.033 SUTAHSS-HSS/CO Material GroupISO 513 P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5 Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC ° x ae 5° x D 4° x D 3° x D 3° x D Vc (m/min) 80÷100 50÷70 35÷55 20÷30 CARBIDE D fz fz fz fz END-MILLS RAMPING (mm) (mm/z) (mm/z) (mm/z) (mm/z) 6 0.017 0.016 0.015 0.021 G2 MDTA 8 0.020 0.019 0.018 0.024 HF VH/UP 10 0.024 0.022 0.021 0.029 MEF 12 0.027 0.025 0.024 0.033 ALU 16 0.031 0.029 0.027 0.037 MEX/MH 20 0.042 0.039 0.037 0.050 UH/MH HSS END-MILLS CARBIDE BURRS PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION 433

Общий каталог Osawa 2018

Общий каталог Osawa 2018