Общий каталог Osawa 2021 - страница 319

Навигация

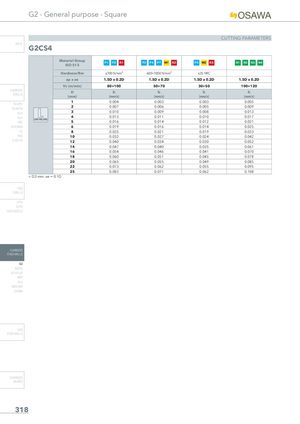

G2 - General purpose - Square CUTTING PARAMETERS INFO G2CS4 Material GroupISO 513 P1 P2 K1 P3 P4 P7 M1 K2 P5 M2 K3 N1 N2 N3 N4 Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ap x ae 1.5D x 0.2D 1.5D x 0.2D 1.5D x 0.2D 1.5D x 0.2D Vc (m/min) 80÷100 50÷70 30÷50 100÷120 CARBIDEDRILLS D fz fz fz fz(mm)(mm/z)(mm/z)(mm/z)(mm/z) 1 0.004 0.003 0.003 0.005 PU-HPU TA-4HTA 2 0.007 0.006 0.005 0.009 SUH 3 0.010 0.009 0.008 0.013 ALH SIDE MILLINGHRC 45 0.0130.016 0.0110.014 0.0100.012 0.0170.021 SUH MINI 6 0.019 0.016 0.014 0.025 HL 8 0.025 0.021 0.019 0.033 HSD 10 0.032 0.027 0.024 0.042 C-SD-TA 12 0.040 0.034 0.030 0.052 14 0.047 0.040 0.035 0.061 16 0.054 0.046 0.041 0.070 18 0.060 0.051 0.045 0.078 20 0.065 0.055 0.049 0.085 22 0.073 0.062 0.055 0.095 25 0.083 0.071 0.062 0.108 < D3 mm: ae = 0.1D HSS DRILLS LFTA SUTA HSS-HSS/CO CARBIDE END-MILLS G2 MDTA HF VH/UP MEF ALU MEX/MH UH/MH HSS END-MILLS CARBIDE BURRS 318

Общий каталог Osawa 2018

Общий каталог Osawa 2018