Общий каталог Mitsubishi 2020 - 2021 - страница 807

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

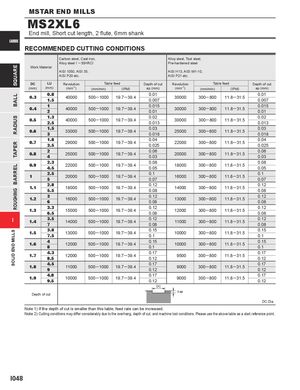

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS MSTAR END MILLS MS2XL6 End mill, Short cut length, 2 flute, 6mm shank CARBIDE RECOMMENDED CUTTING CONDITIONS Carbon steel, Cast iron, Alloy steel, Tool steel, Alloy steel ( ─ 30HRC) Pre-hardened steel Work Material AISI 1050, AISI 35, AISI H13, AISI W1-10, AISI P20 etc. AISI P21 etc. DC LU Revolution Table feed Depth of cut Revolution Table feed Depth of cut (mm) (mm) (min-1) (mm/min) (IPM) ap (mm) (min-1) (mm/min) (IPM) ap (mm) 0.3 0.81.5 40000 500 ─ 1000 19.7 ─ 39.4 0.010.007 30000 300─ 800 11.8─ 31.5 0.010.007 0.4 12 40000 500 ─1000 19.7 ─39.4 0.0150.01 30000 300─ 800 11.8 ─ 31.5 0.0150.01 0.5 1.32.5 40000 500 ─1000 19.7 ─ 39.4 0.020.013 30000 300 ─ 800 11.8─ 31.5 0.020.013 0.6 1.53 33000 500 ─ 1000 19.7 ─39.4 0.030.018 25000 300─ 800 11.8 ─ 31.5 0.030.018 0.7 1.83.5 29000 500 ─1000 19.7 ─39.4 0.040.025 22000 300─ 800 11.8─ 31.5 0.040.025 0.8 24 25000 500─ 1000 19.7─ 39.4 0.060.03 20000 300 ─ 800 11.8─ 31.5 0.060.03 0.9 2.34.5 22000 500 ─1000 19.7 ─ 39.4 0.080.05 18000 300─ 800 11.8 ─ 31.5 0.080.05 1 2.55 20000 500 ─1000 19.7 ─39.4 0.10.07 16000 300 ─ 800 11.8─ 31.5 0.10.07 1.1 2.85.5 18000 500 ─ 1000 19.7 ─39.4 0.120.08 14000 300─ 800 11.8 ─ 31.5 0.120.08 1.2 36 16000 500 ─1000 19.7 ─39.4 0.120.08 13000 300─ 800 11.8 ─ 31.5 0.120.08 1.3 3.36.5 15000 500 ─1000 19.7─ 39.4 0.120.08 12000 300 ─ 800 11.8─ 31.5 0.120.08 I 1.4 3.57 14000 500 ─ 1000 19.7 ─ 39.4 0.120.08 11000 300─ 800 11.8 ─ 31.5 0.120.08 1.5 3.87.5 13000 500 ─1000 19.7 ─39.4 0.150.1 10000 300─ 800 11.8─ 31.5 0.150.1 1.6 48 12000 500─ 1000 19.7 ─ 39.4 0.150.1 10000 300 ─ 800 11.8─ 31.5 0.150.1 1.7 4.38.5 12000 500 ─1000 19.7 ─ 39.4 0.170.12 9500 300 ─ 800 11.8 ─ 31.5 0.170.12 1.8 4.59 11000 500─ 1000 19.7 ─ 39.4 0.170.12 9000 300 ─ 800 11.8─ 31.5 0.170.12 1.9 4.89.5 10000 500 ─1000 19.7 ─ 39.4 0.170.12 9000 300 ─ 800 11.8 ─ 31.5 0.170.12 DC < ap Depth of cut DC:Dia. Note 1) If the depth of cut is smaller than this table, feed rate can be increased. Note 2) Cutting conditions may differ considerably due to the overhang, depth of cut, and machine tool conditions. Please use the above table as a start reference point. I048