Общий каталог Mitsubishi 2020 - 2021 - страница 72

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

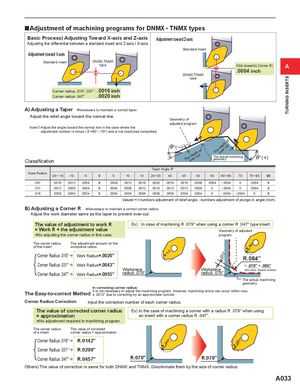

R .047" .002" R .0457" TURNING INSERTS yAdjustment of machining programs for DNMX • TNMX types Basic Process) Adjusting Toward X-axis and Z-axis Adjustment toward Z-axis Adjusting the differential between a standard insert and Z-axis / X-axis. Standard insert Adjustment toward X-axis Standard insert DNMX,TNMX type (Not closed to Corner R) A .0004 inch DNMX,TNMX type Corner radius .016",.031" : .0016 inch Corner radius .047" : .0020 inch A) Adjusting a Taper *Necessary to maintain a correct taper. Adjust the relief angle toward the normal line. Geometry of adjusted program Note1) Adjust the angle toward the normal line in the case where the adjustment number is minus ( ' =60° ─ 70°) and is not machined completely. Classification '°( ─) Theodveepr tchuot f The odveeprthcuotfThe actual machininggeometry'°( +) Taper Angle '° Nose Radius -25─-15 -10 -5 0 5 10 15 20─35 40 45 50 55 60─65 70 75─85 90 .047 .0016 .0012 .0004 0 .0008 .0012 .0016 .0020 .0016 .0016 .0008 .0004 -.0004 0 .0004 0 .031 .0012 .0008 .0004 0 .0004 .0008 .0012 .0016 .0012 .0012 .0008 0 -.0004 0 .0004 0 .016 .0008 .0004 .0004 0 .0004 .0004 .0008 .0008 .0008 .0004 .0004 0 -.0004 -.0004 0 0 Values| + numbers:adjustment of relief angle, -numbers:adjustment of plunge in angle (inch) B) * Adjusting a Corner R Necessary to maintain a correct corner radius. Adjust the work diameter same as the taper to prevent over-cut. The value of adjustment to work R Ex) : In case of machining R .079" when using a corner R .047" type insert. = Work R + the adjustment value Geometry of adjusted *No adjusting the corner radius in this case. program The corner radius The adjustment amount on theof the insertworkpiece radius.Corner Radius .016" |Work Radius+.0020" R 1.2 R .047R.084" Corner Radius .031" | Work Radius+.0043" = .079" + .005" Workpiece Workpiece Work radius Adjusted conditions Corner Radius .047" | Work Radius+.0055" radius .079" radius .079" The actual machining geometry In correcting corner radius: The Easy-to-correct Method It is not necessary to adjust the machining program, however, machining errors can occur within max.± .0012" due to correcting by an approximate number. Corner Radius Correction Input the correction number of each corner radius. The value of corrected corner radius Ex):In the case of machining a corner with a radius R .079" when using = approximation an insert with a corner radius R .047". *No adjustment required in machining program. The corner radius The value of corrected of a insert corner radius = approximation Corner Radius .016" | R.0142" Corner Radius .031" | R.0299" Corner Radius .047" | R.0457" R.079" R.079" Others) The value of correction is same for both DNMX and TNMX. Discriminate them by the size of corner radius. A033