Общий каталог Mitsubishi 2020 - 2021 - страница 708

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

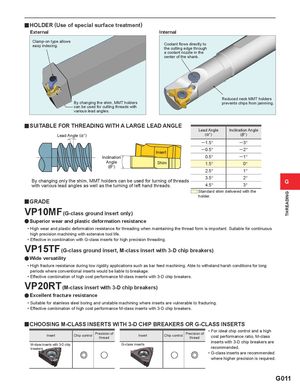

THREADING y HOLDER (Use of special surface treatment) External Internal Clamp-on type allowseasy indexing. Coolant flows directly tothe cutting edge through a coolant nozzle in the center of the shank. Reduced neck MMT holders By changing the shim, MMT holders prevents chips from jamming. can be used for cutting threads with various lead angles. y SUITABLE FOR THREADING WITH A LARGE LEAD ANGLE Lead Angle Inclination Angle Lead Angle (%°) (%°) ('°) ─ 1.5° ─ 3° Insert ─ 0.5° ─ 2° Inclination 0.5° ─ 1° Angle('°) Shim 1.5° 0° 2.5° 1° By changing only the shim, MMT holders can be used for turning of threads 3.5° 2°with various lead angles as well as the turning of left hand threads.4.5°3°G Standard shim delivered with the holder. y GRADE VP10MF (G-class ground insert only) a Superior wear and plastic deformation resistance • High wear and plastic deformation resistance for threading when maintaining the thread form is important. Suitable for continuous high precision machining with extensive tool life. • Effective in combination with G-class inserts for high precision threading. VP15TF (G-class ground insert, M-class insert with 3-D chip breakers) a Wide versatility • High fracture resistance during low rigidity applications such as bar feed machining. Able to withstand harsh conditions for long periods where conventional inserts would be liable to breakage. • Effective combination of high cost performance M-class inserts with 3-D chip breakers. VP20RT (M-class insert with 3-D chip breakers) a Excellent fracture resistance • Suitable for stainless steel boring and unstable machining where inserts are vulnerable to fracturing. • Effective combination of high cost performance M-class inserts with 3-D chip breakers. y CHOOSING M-CLASS INSERTS WITH 3-D CHIP BREAKERS OR G-CLASS INSERTS Insert Chip control Precision ofthread Insert Chip control Precision ofthread• For ideal chip control and a highcost performance ratio, M-class M-class inserts with 3-D chip G-class insertsbreakers inserts with 3-D chip breakers arerecommended. e u u e • G-class inserts are recommendedwhere higher precision is required. G011