Общий каталог Mitsubishi 2020 - 2021 - страница 707

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

THREADING

THREADING

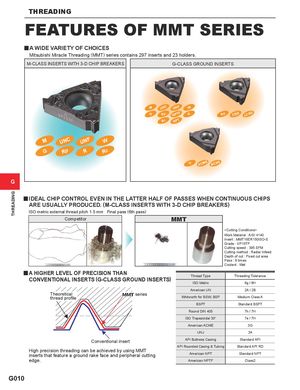

FEATURES OF MMT SERIES

y A WIDE VARIETY OF CHOICES

Mitsubishi Miracle Threading (MMT) series contains 297 inserts and 23 holders.

M-CLASS INSERTS WITH 3-D CHIP BREAKERS G-CLASS GROUND INSERTS

M UNC UNF W

G Rp NPTF R Rd CSG LCSG

Rc NPT

M UNC UNF W

G Rp R Rc

Tr ACME BCSG

G

y IDEAL CHIP CONTROL EVEN IN THE LATTER HALF OF PASSES WHEN CONTINUOUS CHIPS

ARE USUALLY PRODUCED. (M-CLASS INSERTS WITH 3-D CHIP BREAKERS)

ISO metric external thread pitch 1.5 mm Final pass (6th pass)

Competitor MMT