Общий каталог Mitsubishi 2020 - 2021 - страница 673

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

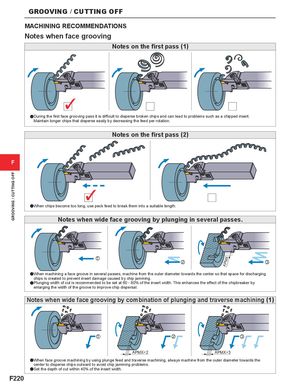

GROOVING / CUTTING OFF APMX GROOVING / CUTTING OFF MACHINING RECOMMENDATIONS Notes when face grooving Notes on the first pass (1) aDuring the first face grooving pass it is difficult to disperse broken chips and can lead to problems such as a chipped insert. Maintain longer chips that disperse easily by decreasing the feed per rotation. Notes on the first pass (2) F aWhen chips become too long, use peck feed to break them into a suitable length. Notes when wide face grooving by plunging in several passes. z x c aWhen machining a face groove in several passes, machine from the outer diameter towards the center so that space for discharging chips is created to prevent insert damage caused by chip jamming. aPlunging width of cut is recommended to be set at 60 - 80% of the insert width. This enhances the effect of the chipbreaker by enlarging the width of the groove to improve chip dispersal. Notes when wide face grooving by combination of plunging and traverse machining (1) z x c APMX×2 APMX×3 aWhen face groove machining by using plunge feed and traverse machining, always machine from the outer diameter towards the center to disperse chips outward to avoid chip jamming problems. aSet the depth of cut within 40% of the insert width. F220