Общий каталог Mitsubishi 2020 - 2021 - страница 672

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

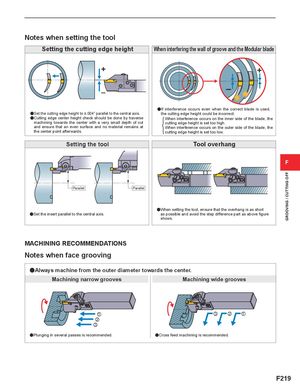

GROOVING / CUTTING OFF Notes when setting the tool Setting the cutting edge height When interfering the wall of groove and the Modular blade + + – – aIf interference occurs even when the correct blade is used, aSet the cutting edge height to ±.004" parallel to the central axis. the cutting edge height could be incorrect. aCutting edge center height check should be done by traverse When interference occurs on the inner side of the blade, the machining towards the center with a very small depth of cut cutting edge height is set too high. and ensure that an even surface and no material remains at When interference occurs on the outer side of the blade, the the center point afterwards. cutting edge height is set too low. Setting the tool Tool overhang F Parallel Parallel aWhen setting the tool, ensure that the overhang is as short aSet the insert parallel to the central axis. as possible and avoid the step difference part as above figure shows. MACHINING RECOMMENDATIONS Notes when face grooving aAlways machine from the outer diameter towards the center. Machining narrow grooves Machining wide grooves z c x z x c aPlunging in several passes is recommended. aCross feed machining is recommended. F219