Общий каталог Mitsubishi 2020 - 2021 - страница 252

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

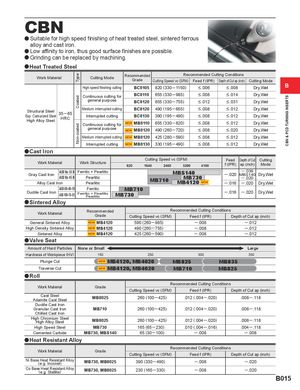

TypeCoatedNon-coated CBN & PCD TURNING INSERTS CBN a Suitable for high speed finishing of heat treated steel, sintered ferrous alloy and cast iron. a Low affinity to iron, thus good surface finishes are possible. a Grinding can be replaced by machining. aHeat Treated Steel Work Material Cutting Mode Recommended Recommended Cutting ConditionsGradeCutting Speed vc (SFM)Feed f (IPR)Depth of Cut ap (inch)Cutting Mode High speed finishing cutting BC8105 820 (330 ─ 1150) < .006 < .008 Dry,Wet B Continuous cutting for BC8110 655 (330 ─ 985) < .008 < .014 Dry,Wet general purpose BC8120 655 (330 ─ 755) < .012 < .031 Dry,Wet Structural SteelEsp. Carburized SteelHigh Alloy Steel35 ─ 65HRCMedium interrupted cuttingInterrupted cuttingContinuous cutting forBC8120490 (195 ─ 655)BC8130390 (195 ─ 490)MB8110655 (330 ─ 820)< .008< .008< .008< .012Dry,Wet< .012Dry,Wet< .012Dry,Wet general purpose MB8120 490 (260 ─ 720) < .008 < .020 Dry,Wet Medium interrupted cutting MB8120 425 (280 ─ 590) < .008 < .012 Dry,Wet Interrupted cutting MB8130 330 (195 ─ 490) < .008 < .012 Dry,Wet aCast Iron Work Material Work Structure Cutting Speed vc (SFM) Feed Depth of Cut Cutting8201640246032804100f (IPR)ap (inch)Mode Gray Cast Iron AISI No 35 B Ferritic + PearliticAISI No 45 BPearliticAlloy Cast IronPearlitic MBS140MB710MB730MB4120 ─ .039─ .020MBS140Dry,Wet─ .020─ .016─ .020Dry,Wet AISI 60-40-18 FerriticDuctile Cast IronAISI 100-70-03Ferritic + PearliticPearliticMB710MB730 ─ .016 ─ .020 Dry,Wet aSintered Alloy Work Material Recommended Recommended Cutting ConditionsGradeCutting Speed vc (SFM)Feed f (IPR)Depth of Cut ap (inch) General Sintered Alloy MB4120 590 (260 ─ 985) ─ .008 ─ .012 High Density Sintered Alloy MB4120 490 (260 ─ 755) ─ .008 ─ .012 Sintered Alloy MB4120 425 (260 ─ 590) ─ .008 ─ .012 aValve Seat Amount of Hard Particles None or Small Large Hardness of Workpiece (HV) 150 250 300 350 Plunge Cut MB4120, MB4020 MB825 MB835 Traverse Cut MB4120, MB4020 MB710 MB825 a Roll Recommended Cutting Conditions Work Material Grade Cutting Speed vc (SFM) Feed f (IPR) Depth of Cut ap (inch) Cast SteelAdamite Cast Steel MB8025 260 (100 ─ 425) .012 (.004 ─ .020) .008 ─ .118 Ductile Cast Iron Granular Cast Iron MB710 260 (100 ─ 425) .012 (.004 ─ .020) .008 ─ .118 Chilled Cast Iron High Chromium SteelHigh Alloy Steel MB8025 260 (100 ─ 425) .012 (.004 ─ .020) .008 ─ .118 High Speed Steel MB730 165 (65 ─ 230) .010 (.004 ─ .016) .004 ─ .118 Cemented Carbide MB730, MBS140 65 (30 ─ 100) ─ .008 ─ .008 aHeat Resistant Alloy Recommended Cutting Conditions Work Material Grade Cutting Speed vc (SFM) Feed f (IPR) Depth of Cut ap (inch) Ni Base Heat Resistant Alloy(e.g. Inconel) MB730, MB8025 390 (330 ─ 490) ─ .008 ─ .020 Co Base Heat Resistant Alloy(e.g. Stellite) MB730, MB8025 230 (165 ─ 330) ─ .008 ─ .020 B015