Общий каталог Mitsubishi 2020 - 2021 - страница 251

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

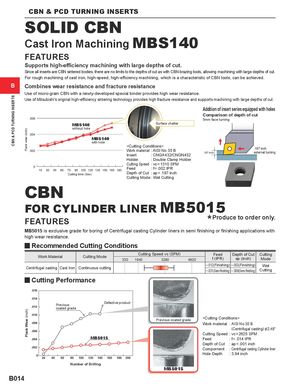

CBN & PCD TURNING INSERTS

Flank wear (inch)Flank Wear (inch)

CBN & PCD TURNING INSERTS

SOLID CBN

Cast Iron Machining MBS140

FEATURES

Supports high-efficiency machining with large depths of cut.

Since all inserts are CBN sintered bodies, there are no limits to the depths of cut as with CBN brazing tools, allowing machining with large depths of cut.

For rough machining of cast iron, high-speed, high-efficiency machining, which is a characteristic of CBN tools, can be achieved.

B Combines wear resistance and fracture resistance

Use of micro-grain CBN with a newly-developed special binder provides high wear resistance.

Use of Mitsubishi's original high-efficiency sintering technology provides high fracture resistance and supports machining with large depths of cut.

Addition of insert series equipped with holes

Comparison of depth of cut

.006 5mm face turning

MBS140 Surface chatter

without hole

.004

MBS140

with hole

.002