Общий каталог Mitsubishi 2020 - 2021 - страница 1730

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

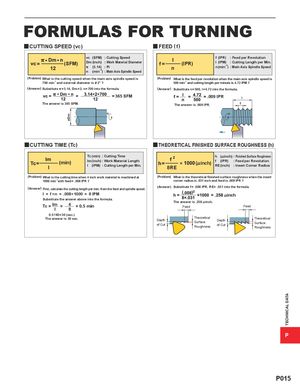

øDm TECHNICAL DATA FORMULAS FOR TURNING y CUTTING SPEED (vc) y FEED ( f ) vc (SFM) : Cutting Speed f (IPR) : Feed per Revolution (SFM) Dm (inch) : Work Material Diameter)(3.14): Pi (IPR) I (IPM) : Cutting Length per Min.n (min-1) : Main Axis Spindle Speed n (min-1) : Main Axis Spindle Speed (Problem) What is the cutting speed when the main axis spindle speed is (Problem) What is the feed per revolution when the main axis spindle speed is 700 min-1 and external diameter is & 2" ? 500 min-1 and cutting length per minute is 4.72 IPM ? (Answer) Substitute ) =3.14, Dm =2, n= 700 into the formula. (Answer) Substitute n=500, I=4.72 into the formula. 365 SFM .009 IPR l The answer is 365 SFM. The answer is .009 IPR. f n n yCUTTING TIME (Tc) y THEORETICAL FINISHED SURFACE ROUGHNESS (h) Tc (min) : Cutting Time h (!inch) : Finished Surface Roughness (min) Im (inch) : Work Material LengthI(IPM): Cutting Length per Min.8RE (!inch) f (IPR)RE (inch): Feed per Revolution: Insert Corner Radius (Problem) What is the cutting time when 4 inch work material is machined at (Problem) What is the theoretical finished surface roughness when the insert 1000 min-1 with feed= .008 IPR ? corner radius is .031 inch and feed is .008 IPR ? (Answer) First, calculate the cutting length per min. from the feed and spindle speed. (Answer) Substitute f= .008 IPR, RE= .031 into the formula. I = f ×n = .008× 1000 = 8 IPM !inch Substitute the answer above into the formula. Tc = Iml = 48 = 0.5 min The answer is .258 !inch.Feed Feed 0.5 x60 = 30 (sec.) The answer is 30 sec. Depthof Cut TheoreticalSurfaceDepthRoughnessof Cut TheoreticalSurfaceRoughness P P015