Общий каталог Mitsubishi 2020 - 2021 - страница 1665

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

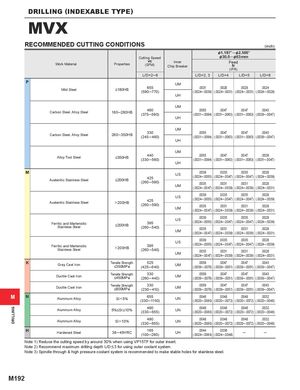

DRILLING (INDEXABLE TYPE) MVX RECOMMENDED CUTTING CONDITIONS (inch) &1.187" ─ &2.500" Cutting Speed &30.0 ─ &63 mm Work Material Properties vc Inner(SFM)Chip Breaker Feedfr (IPR) L/D=2─6 L/D=2, 3 L/D=4 L/D=5 L/D=6 P UM Mild Steel ≤180HB 655(590─770) .0031 .0028 .0028 .0024(.0024─.0039)(.0024─.0031)(.0024─.0031)(.0024─.0028) UH UM Carbon Steel, Alloy Steel 180─280HB 460(375─590) .0055 .0047 .0047 .0043(.0031─.0094)(.0031─.0063)(.0031─.0063)(.0039─.0047) UH UM Carbon Steel, Alloy Steel 280─350HB 330(245─460) .0055 .0047 .0047 .0043(.0031─.0094)(.0031─.0063)(.0031─.0063)(.0039─.0047) UH UM Alloy Tool Steel ≤350HB 440(330─560) .0055 .0047 .0047 .0039(.0031─.0094)(.0031─.0063)(.0031─.0063)(.0031─.0047) UH M Austenitic Stainless Steel ≤200HB 425(260─590) US .0039 .0035 .0035 .0028(.0024─.0055)(.0024─.0047)(.0024─.0047)(.0024─.0039)UM.0035.0031.0031.0028(.0024─.0047)(.0024─.0039)(.0024─.0039)(.0024─.0031) Austenitic Stainless Steel >200HB 425(260─590) US .0039 .0035 .0035 .0028(.0024─.0055)(.0024─.0047)(.0024─.0047)(.0024─.0039)UM.0035.0031.0031.0028(.0024─.0047)(.0024─.0039)(.0024─.0039)(.0024─.0031) Ferritic and MartensiticStainless Steel≤200HB 395(260─540) US .0039 .0035 .0035 .0028(.0024─.0055)(.0024─.0047)(.0024─.0047)(.0024─.0039)UM.0035.0031.0031.0028(.0024─.0047)(.0024─.0039)(.0024─.0039)(.0024─.0031) Ferritic and MartensiticStainless Steel>200HB 395(260─540) US .0039 .0035 .0035 .0028(.0024─.0055)(.0024─.0047)(.0024─.0047)(.0024─.0039)UM.0035.0031.0031.0028(.0024─.0047)(.0024─.0039)(.0024─.0039)(.0024─.0031) K Gray Cast Iron Tensile Strength 525≤350MPa(425 ─ 6 40)UM .0059 .0047 .0047 .0043(.0039─.0079)(.0039─.0051)(.0039─.0051)(.0039─.0047) Ductile Cast Iron Tensile Strength 330≤450MPa(260─440)UM .0059 .0047 .0047 .0043(.0039─.0079)(.0039─.0051)(.0039─.0051)(.0039─.0047) Ductile Cast Iron Tensile Strength 330≤800MPa(230─410)UM .0059 .0047 .0047 .0043(.0039─.0079)(.0039─.0051)(.0039─.0051)(.0039─.0047) M N Aluminum Alloy Si < 5% 655(330─1150) UN .0048 .0048 .0048 .0032(.0020─.0080)(.0020─.0072)(.0020─.0072)(.0020─.0048) Aluminum Alloy 5%≤Si ≤10% 490(330 ─ 655) UN .0048 .0048 .0048 .0032(.0020─.0080)(.0020─.0072)(.0020─.0072)(.0020─.0048) Aluminum Alloy Si >10% 490(330 ─ 655) UN .0048 .0048 .0048 .0032(.0020─.0080)(.0020─.0072)(.0020─.0072)(.0020─.0048) H Hardened Steel 38─45HRC 165(100─260) UH .0044 .0036(.0024─.0064)(.0024─.0048)── Note 1) Reduce the cutting speed by around 30% when using VP15TF for outer insert. Note 2) Recommend maximum drilling depth L/D < 3 for using outer coolant system. Note 3) Spindle through & high pressure coolant system is recommended to make stable holes for stainless steel. M192 DRILLING