Общий каталог Mitsubishi 2020 - 2021 - страница 1466

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

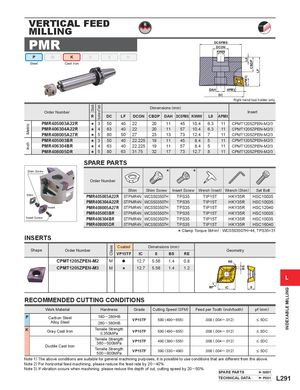

MetricInch Stock Number of Teeth Class BS L8(APMX) CBDP LF INDEXABLE MILLING VERTICAL FEED MILLING PMR DCSFMSDCON KWW P M K N S H Steel Cast Iron DAH APMX DC Right hand tool holder only. Dimensions (mm) Order Number Insert R DC LF DCON CBDP DAH DCSFMS KWW L8 APMX PMR405003A22R s 3 50 40 22 20 11 45 10.4 6.3 11 CPMT1205ZPEN-M2/3 PMR406304A22R s 4 63 40 22 20 11 57 10.4 6.3 11 CPMT1205ZPEN-M2/3 PMR408005A27R s 5 80 50 27 23 13 73 12.4 7 11 CPMT1205ZPEN-M2/3 PMR405003BR s 3 50 40 22.225 19 11 45 8.4 5 11 CPMT1205ZPEN-M2/3 PMR406304BR s 4 63 40 22.225 19 11 57 8.4 5 11 CPMT1205ZPEN-M2/3 PMR408005DR s 5 80 63 31.75 32 17 73 12.7 8 11 CPMT1205ZPEN-M2/3 SPARE PARTS Shim Screw * * Order Number Shim Shim Screw Insert Screw Wrench (Insert) Wrench (Shim) Set Bolt Shim PMR405003A22R STPMR4N WCS503507H TPS35 TIP15T HKY35R HSC10035 PMR406304A22R STPMR4N WCS503507H TPS35 TIP15T HKY35R HSC10035 Insert PMR408005A27R STPMR4N WCS503507H TPS35 TIP15T HKY35R HSC12040 PMR405003BR STPMR4N WCS503507H TPS35 TIP15T HKY35R HSC10035 Insert Screw PMR406304BR STPMR4N WCS503507H TPS35 TIP15T HKY35R HSC10035 PMR408005DR STPMR4N WCS503507H TPS35 TIP15T HKY35R HSC16040 * Clamp Torque (lbf-in) : WCS503507H=44, TPS35=31 INSERTS Coated Dimensions (mm) Shape Order Number Geometry VP15TF IC S BS RE CPMT1205ZPEN-M2 M a 12.7 5.56 1.4 0.8 RE CPMT1205ZPEN-M3 M s 12.7 5.56 1.4 1.2 L IC S RECOMMENDED CUTTING CONDITIONS Work Material Hardness Grade Cutting Speed (SFM) Feed per Tooth (inch/tooth) pf (mm) P Carbon SteelAlloy Steel 180─ 280HB280─ 380HB VP15TF 590 (490─655) .008 (.004─.012) < .5DC K Gray Cast Iron Tensile Strength< 350MPa VP15TF 590 (490─655) .008 (.004─.012) < .5DC Ductile Cast Iron Tensile Strength360─ 500MPa VP15TF 490 (390─ 555) .008 (.004─.012) < .5DC Tensile Strength500─ 800MPa VP15TF 390 (330─ 490) .008 (.004─.012) < .5DC Note 1) The above conditions are suitable for general machining purposes, it is possible to use conditions that are different from the above. Note 2) For horizontal feed machining, please reduce the feed rate by 20 ─ 40%. Note 3) If vibration occurs when machining, please reduce the depth of cut, cutting speed by 20 ─ 50%. SPARE PARTS N001 TECHNICAL DATA P001 L291