Общий каталог Mitsubishi 2020 - 2021 - страница 1456

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

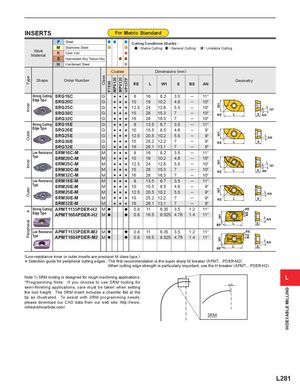

TypeInnerOuterInnerOuterPeripheral Class F7030 MP6120 MP9120 VP15TF W1W1W1W1W1W1 BSBS INDEXABLE MILLING INSERTS For Metric Standard P Steel Cutting Conditions (Guide) : M Stainless SteelWorkMaterialKCast Iron : Stable Cutting : General Cutting : Unstable Cutting S Heat-resistant Alloy, Titanium Alloy H Hardened Steel Coated Dimensions (mm) Shape Order Number Geometry RE L W1 S BS AN Strong Cutting SRG16C G s s s 8 16 8.2 3.5 ─ 11° Edge Type SRG20C G s s s 10 19 10.2 4.6 ─ 10° SRG25C G s s s 12.5 24 12.8 5.5 ─ 10° 18° SRG30C G s s s 15 28 15.3 7 ─ 10° RE L S AN SRG32C G s s s 16 28 16.3 7 ─ 10° Strong Cutting SRG16E G s s s 8 13.5 6.7 3.5 ─ 11° Edge Type SRG20E G s s s 10 15.5 8.5 4.6 ─ 9° SRG25E G s s s 12.5 20.5 10.2 5.5 ─ 9° AN SRG30E G s s s 15 25.2 12.2 7 ─ 9° RE L S SRG32E G s s s 16 26.1 13.1 7 ─ 9° Low Resistance SRM16C-M M s s s 8 16 8.2 3.5 ─ 11° Type SRM20C-M M s s s 10 19 10.2 4.6 ─ 10° SRM25C-M M s s s 12.5 24 12.8 5.5 ─ 10° 18° SRM30C-M M s s s 15 28 15.3 7 ─ 10° RE L S AN SRM32C-M M s s s 16 28 16.3 7 ─ 10° Low Resistance SRM16E-M M s s s 8 13.5 6.7 3.5 ─ 11° Type SRM20E-M M s s s 10 15.5 8.5 4.6 ─ 9° SRM25E-M M s s s 12.5 20.5 10.2 5.5 ─ 9° AN SRM30E-M M s s s 15 25.2 12.2 7 ─ 9° RE L S SRM32E-M M s s s 16 26.1 13.1 7 ─ 9° * Strong CuttingEdge TypeAPMT1135PDER-H2APMT1604PDER-H2M aMa a 0.8 11 6.35 3.5 1.2 11°a0.816.59.5254.761.411° RE AN L S Low Resistance APMT1135PDER-M2 M a a 0.8 11 6.35 3.5 1.2 11° RE Type APMT1604PDER-M2 M a a 0.8 16.5 9.525 4.76 1.4 11° AN L S (Low-resistance inner or outer inserts are precision M class type.) * Selection guide for peripheral cutting edges : The first recommendation is When cutting edge strength the super sharp M breaker (APMT....PDER-M2). is particularly important, use the H breaker (APMT....PDER-H2). Note 1) SRM tooling is designed for rough machining applications. L *Programming Note: If you choose to use SRM tooling for semi-finishing applications, care must be taken when setting the tool height. The SRM insert includes a chamfer flat at the tip as illustrated. To assist with SRM programming needs, please download our CAD data from our web site; http://www. mitsubishicarbide.com/ SRM L281