Общий каталог Mitsubishi 2020 - 2021 - страница 1426

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

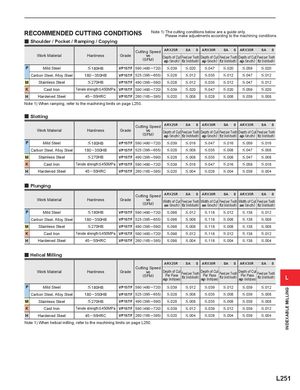

RECOMMENDED CUTTING CONDITIONS Note 1) The cutting conditions below are a guide only.Please make adjustments according to the machining conditions. y Shoulder / Pocket / Ramping / Copying Cutting Speed ARX25RpppSAppS ARX30RpppSAppS ARX35RpppSAppS Work Material Hardness Grade vc(SFM) Depth of Cut Feed per Tooth Depth of Cut Feed per Tooth Depth of Cut Feed per Toothap (inch)fz (inch/tooth)ap (inch)fz (inch/tooth)ap (inch)fz (inch/tooth) P Mild Steel < 180HB VP15TF 590 (490─720) <.039 <.020 <.047 <.020 <.059 <.020 Carbon Steel, Alloy Steel 180─ 350HB VP15TF 525 (395 ─ 655) <.028 <.012 <.035 <.012 <.047 <.012 M Stainless Steel < 270HB VP15TF 490 (395 ─ 590) <.028 <.012 <.035 <.012 <.047 <.012 K Cast Iron Tensile strength<450MPa VP15TF 590 (490 ─ 720) <.039 <.020 <.047 <.020 <.059 <.020 H Hardened Steel 45─ 55HRC VP15TF 260 (165 ─ 395) <.020 <.008 <.028 <.008 <.039 <.008 Note 1) When ramping, refer to the machining limits on page L250. y Slotting Cutting Speed ARX25RpppSAppS ARX30RpppSAppS ARX35RpppSAppS Work Material Hardness Grade vc(SFM) Depth of Cut Feed per Tooth Depth of Cut Feed per Tooth Depth of Cut Feed per Toothap (inch)fz (inch/tooth)ap (inch)fz (inch/tooth)ap (inch)fz (inch/tooth) P Mild Steel < 180HB VP15TF 590 (490─ 720) <.039 <.016 <.047 <.016 <.059 <.016 Carbon Steel, Alloy Steel 180─ 350HB VP15TF 525 (395 ─ 655) <.028 <.008 <.035 <.008 <.047 <.008 M Stainless Steel < 270HB VP15TF 490 (395 ─ 590) <.028 <.008 <.035 <.008 <.047 <.008 K Cast Iron Tensile strength<450MPa VP15TF 590 (490 ─ 720) <.039 <.016 <.047 <.016 <.059 <.016 H Hardened Steel 45─ 55HRC VP15TF 260 (165 ─ 395) <.020 <.004 <.028 <.004 <.039 <.004 y Plunging Cutting Speed ARX25RpppSAppS ARX30RpppSAppS ARX35RpppSAppS Work Material Hardness Grade vc(SFM) Width of Cut Feed per Tooth Width of Cut Feed per Tooth Width of Cut Feed per Toothae (inch)fz (inch/tooth)ae (inch)fz (inch/tooth)ae (inch)fz (inch/tooth) P Mild Steel < 180HB VP15TF 590 (490─ 720) <.098 <.012 <.118 <.012 <.138 <.012 Carbon Steel, Alloy Steel 180─ 350HB VP15TF 525 (395 ─ 655) <.098 <.008 <.118 <.008 <.138 <.008 M Stainless Steel < 270HB VP15TF 490 (395 ─ 590) <.098 <.008 <.118 <.008 <.138 <.008 K Cast Iron Tensile strength<450MPa VP15TF 590 (490 ─ 720) <.098 <.012 <.118 <.012 <.138 <.012 H Hardened Steel 45─ 55HRC VP15TF 260 (165 ─ 395) <.098 <.004 <.118 <.004 <.138 <.004 y Helical Milling ARX25RpppSAppS ARX30RpppSAppS ARX35RpppSAppS Cutting Speed Work Material Hardness Grade vc(SFM) Depth of Cut Per Pass ap (inch/pass) Feed per Tooth fz (inch/tooth) Depth of Cut Per Pass ap (inch/pass) Feed per Tooth fz (inch/tooth) Depth of Cut Per Pass ap (inch/pass) Feed per Tooth fz (inch/tooth) L P Mild Steel < 180HB VP15TF 590 (490─ 720) <.039 <.012 <.039 <.012 <.039 <.012 Carbon Steel, Alloy Steel 180─ 350HB VP15TF 525 (395 ─ 655) <.028 <.008 <.035 <.008 <.039 <.008 M Stainless Steel < 270HB VP15TF 490 (395 ─ 590) <.028 <.008 <.035 <.008 <.039 <.008 K Cast Iron Tensile strength<450MPa VP15TF 590 (490 ─ 720) <.039 <.012 <.039 <.012 <.039 <.012 H Hardened Steel 45─ 55HRC VP15TF 260 (165 ─ 395) <.020 <.004 <.028 <.004 <.039 <.004 Note 1) When helical milling, refer to the machining limits on page L250. L251 INDEXABLE MILLING