Общий каталог Mitsubishi 2020 - 2021 - страница 1425

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

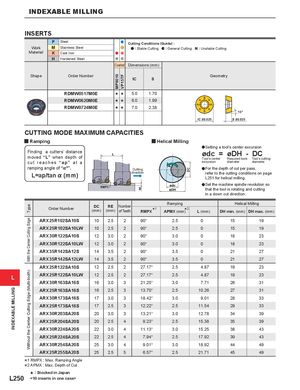

INDEXABLE MILLING TypeWith the Center Cutting EdgeWithout the Center Cutting Edge (Multi-tooth) MP8010 VP15TF ap DC INDEXABLE MILLING INSERTS P Steel Cutting Conditions (Guide) : Work M Stainless Steel : Stable Cutting : General Cutting : Unstable Cutting Material K Cast Iron H Hardened Steel Coated Dimensions (mm) Shape Order Number Geometry IC S RDMW0517M0E s s 5.0 1.70 RDMW0620M0E s s 6.0 1.99 RDMW0724M0E s s 7.0 2.38 15° IC ±0.025 S ±0.025 CUTTING MODE MAXIMUM CAPACITIES y Ramping y Helical Milling a Setting a tool’s center excursion Finding a cutters’ distancemoved “L” when depth of ødc = øDH - DCTool’s centerRequired boreTool’s cutting cut reaches “ap” at a excursion diameter diameter ramping angle of “%°”. Cutting a For the depth of cut per pass, L=ap/tan % (mm) direction refer to the cutting conditions on pageL251 for helical milling. RMPX a Set the machine spindle revolution sothat the tool is rotating and cutting in a down cut direction. Order Number DC RE Number(mm)(mm)of Teeth RampingRMPX *1APMX (mm*) 2L (mm) Helical MillingDH min. (mm)DH max. (mm) ARX 25R102SA10S 10 2.5 2 90° 2.5 0 15 19 ARX 25R102SA10LW 10 2.5 2 90° 2.5 0 15 19 ARX 30R122SA10S 12 3.0 2 90° 3.0 0 18 23 ARX 30R122SA10LW 12 3.0 2 90° 3.0 0 18 23 ARX 35R142SA12S 14 3.5 2 90° 3.5 0 21 27 ARX 35R142SA12LW 14 3.5 2 90° 3.5 0 21 27 ARX 25R122SA10S 12 2.5 2 27.17° 2.5 4.87 19 23 L ARX 25R122SA10LW 12 2.5 2 27.17° 2.5 4.87 19 23 ARX 30R163SA16S 16 3.0 3 21.25° 3.0 7.71 26 31 ARX 25R163SA16S 16 2.5 3 13.70° 2.5 10.26 27 31 ARX 30R173SA16S 17 3.0 3 18.42° 3.0 9.01 28 33 ARX 25R173SA16S 17 2.5 3 12.22° 2.5 11.54 29 33 ARX 30R203SA20S 20 3.0 3 13.21° 3.0 12.78 34 39 ARX 25R204SA20S 20 2.5 4 9.23° 2.5 15.38 35 39 ARX 30R224SA20S 22 3.0 4 11.13° 3.0 15.25 38 43 ARX 25R224SA20S 22 2.5 4 7.94° 2.5 17.92 39 43 ARX 30R254SA20S 25 3.0 4 9.01° 3.0 18.92 44 49 ARX 25R255SA20S 25 2.5 5 6.57° 2.5 21.71 45 49 **12 RMPX APMX :: Max. Max. Ramping Angle Depth of Cut s : Stocked in Japan L250 <10 inserts in one case>