Общий каталог Mitsubishi 2020 - 2021 - страница 1395

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

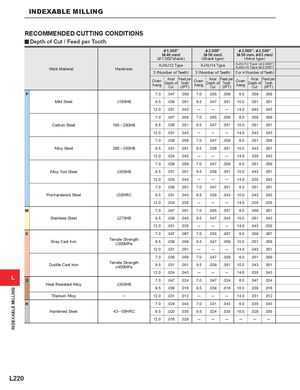

INDEXABLE MILLING RECOMMENDED CUTTING CONDITIONS y Depth of Cut / Feed per Tooth & 1.500" & 2.000" & 2.000", &2.500" (& 40 mm) (& 50 mm) (& 50 mm, &63 mm) (& 1.500"shank) (Shank type) (Arbor type) Work Material Hardness AJXU12 Type AJXU14 Type AJXU12 Type ( & 2.000")AJXU14 Type (& 2.500") 3 (Number of Teeth) 3 (Number of Teeth) 3 or 4 (Number of Teeth) Over-hangAxial Feed perDepth ofToothCut(IPT)Over-hangAxialFeed perDepth ofToothCut(IPT)Over-hangAxialFeed perDepth ofToothCut(IPT) P 7.0 .047 .059 7.0 .055 .059 6.0 .059 .059 Mild Steel ≤180HB 9.5 .039 .051 9.5 .047 .051 10.0 .051 .051 12.0 .031 .043 ─ ─ ─ 14.0 .043 .043 7.0 .047 .059 7.0 .055 .059 6.0 .059 .059 Carbon Steel 180 ─ 280HB 9.5 .039 .051 9.5 .047 .051 10.0 .051 .051 12.0 .031 .043 ─ ─ ─ 14.0 .043 .043 7.0 .039 .059 7.0 .047 .059 6.0 .051 .059 Alloy Steel 280 ─ 350HB 9.5 .031 .051 9.5 .039 .051 10.0 .043 .051 12.0 .024 .043 ─ ─ ─ 14.0 .035 .043 7.0 .039 .059 7.0 .047 .059 6.0 .051 .059 Alloy Tool Steel ≤350HB 9.5 .031 .051 9.5 .039 .051 10.0 .043 .051 12.0 .024 .043 ─ ─ ─ 14.0 .035 .043 7.0 .039 .051 7.0 .047 .051 6.0 .051 .051 Pre-hardened Steel ≤35HRC 9.5 .031 .043 9.5 .039 .043 10.0 .043 .043 12.0 .024 .035 ─ ─ ─ 14.0 .035 .035 M 7.0 .047 .051 7.0 .055 .051 6.0 .059 .051 Stainless Steel ≤270HB 9.5 .039 .043 9.5 .047 .043 10.0 .051 .043 12.0 .031 .035 ─ ─ ─ 14.0 .043 .035 K 7.0 .047 .067 7.0 .055 .067 6.0 .059 .067 Gray Cast Iron Tensile Strength≤350MPa 9.5 .039 .059 9.5 .047 .059 10.0 .051 .059 12.0 .031 .051 ─ ─ ─ 14.0 .043 .051 7.0 .039 .059 7.0 .047 .059 6.0 .051 .059 Ductile Cast Iron Tensile Strength≤450MPa 9.5 .031 .051 9.5 .039 .051 10.0 .043 .051 12.0 .024 .043 ─ ─ ─ 14.0 .035 .043 L S 7.0 .047 .024 7.0 .047 .024 6.0 .047 .024 Heat Resistant Alloy ≤350HB 9.5 .039 .016 9.5 .039 .016 10.0 .039 .016 Titanium Alloy ─ 12.0 .031 .012 ─ ─ ─ 14.0 .031 .012 H 7.0 .024 .043 7.0 .031 .043 6.0 .035 .043 Hardened Steel 43 ─ 55HRC 9.5 .020 .035 9.5 .024 .035 10.0 .028 .035 12.0 .016 .028 ─ ─ ─ ─ ─ ─ L220 INDEXABLE MILLING