Общий каталог Mitsubishi 2020 - 2021 - страница 1370

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

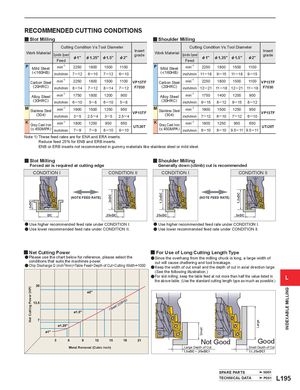

.5xDCNet Cutting Power (HP) .2xDC 1.2xDC Small 1.2xDC Large INDEXABLE MILLING RECOMMENDED CUTTING CONDITIONS y Slot Milling y Shoulder Milling Cutting Condition Vs.Tool Diameter Cutting Condition Vs.Tool Diameter Work Material Spindle SpeedFeed& 1" & 1.25" & 1.5" & 2" InsertgradeWork Material Spindle SpeedFeed& 1" & 1.25" & 1.5" & 2" Insertgrade P Mild Steel min-1 2250 1800 1500 1100 P Mild Steel min-1 2250 1800 1500 1100 (<160HB) inch/min 7 ─12 6 ─10 7 ─12 6 ─10 (<160HB) inch/min 11─18 9─15 11─18 9─ 15 Carbon Steel min-1 2250 1800 1500 1100 VP15TF Carbon Steel min-1 2250 1800 1500 1100 VP15TF (20HRC) inch/min 8─14 7 ─12 8 ─14 7 ─12 F7030 (20HRC) inch/min 12─21 11─18 12─21 11─ 18 F7030 Alloy Steel min-1 1750 1800 1200 900 Alloy Steel min-1 1750 1400 1200 900 (30HRC) inch/min 6─10 5─8 6─10 5─8 (30HRC) inch/min 9─15 8─12 9─15 8─12 M Stainless Steel min-1 1900(304)inch/min3─515002.5 ─412503─5950VP15TF2.5 ─4M Stainless Steel min-1 1900(304)inch/min7─1215006─1012507─12950 VP15TF6─10 K Gray Cast Iron min-1 1800(< 450MPA)inch/min7─912507─9950650 UTi20T8 ─108─10KGray Cast Iron min-1 1800(< 450MPA)inch/min8─101250950 650 UTi20T8─109.5─119.5─11 Note 1) These feed rates are for ENA and ERA inserts. Reduce feed 25% for ENB and ERB inserts. ENB or ERB inserts not recommended in gummy materials like stainless steel or mild steel. y Slot Milling y Shoulder Milling Forced air is required at cutting edge Generally down (climb) cut is recommended CONDITION I CONDITION II CONDITION I CONDITION II (NOTE FEED RATE) (NOTE FEED RATE) DC .25xDC .25xDC .5xDC a Use higher recommended feed rate under CONDITION I. a Use higher recommended feed rate under CONDITION I. a Use lower recommended feed rate under CONDITION II. a Use lower recommended feed rate under CONDITION II. y Net Cutting Power y For Use of Long Cutting Length Type aPlease use the chart below for reference, please select the aSince the overhang from the milling chuck is long, a large width of conditions that suits the machines power.aChip Discharge Q (inch3/min)=Table Feed×Depth of Cut×Cutting Width÷1000cut will cause chattering and tool breakage.aKeep the width of cut small and the depth of cut in axial direction large. (See the following illustration.) aFor slot milling, keep the table feed at not more than half the value listed inthe above table. (Use the standard cutting length type as much as possible.)L (Steel 230HB) Not Good Good Metal Removal (Cubic inch) Large Depth of Cut Small Depth of Cut (.5xDC .25xDC) (< .25xDC) SPARE PARTS N001 TECHNICAL DATA P001 L195