Общий каталог Mitsubishi 2020 - 2021 - страница 1368

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

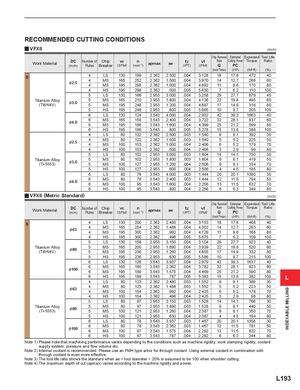

RECOMMENDED CUTTING CONDITIONS y VFX6 (inch) Chip Removal Estimated Expected Tool Life Work Material DC Number of Chip vc(inch)FlutesBreaker(SFM)n(min-1)apmaxaefz vf(IPT)(IPM)Rate Cutting Power Torque RatioQPC (inch3/min) (HP) (lbf-ft) (%) S 4 LS 130 199 2.362 2.500 .004 3.128 18 17.8 472 40 &2.5 44 MS 165 252 2.362 1.500 .004 3.970 14 12.7 266 60MS1952982.3621.000.0044.692119.617080 4 HS 195 298 2.362 .500 .005 5.630 7 6.2 110 100 5 LS 130 166 2.953 3.000 .004 3.258 29 27.7 879 40 Titanium Alloy(Ti6Al4V)&3.0 55 MS 165 210 2.953 1.800 .004 4.136 22 19.8 495 60MS1952482.9531.200.0044.8871714.931680 5 HS 195 248 2.953 .600 .005 5.865 10 9.7 205 100 6 LS 130 124 3.543 4.000 .004 2.932 42 39.3 1663 40 &4.0 66 MS 165 158 3.543 2.400 .004 3.722 32 28.1 937 60MS1951863.5431.600.0044.3992521.259980 6 HS 195 186 3.543 .800 .005 5.278 15 13.8 388 100 4 LS 80 122 2.362 2.500 .003 1.540 9 9.1 392 30 &2.5 44 MS 80 122 2.362 1.500 .003 1.540 5MS1001532.3621.000.0042.40665.2225 505.217970 4 HS 100 153 2.362 .500 .004 2.406 3 2.9 99 80 5 LS 80 102 2.953 3.000 .003 1.604 14 14.1 730 30 Titanium Alloy(Ti-5553)&3.0 55 MS 80 102 2.953 1.800 .003 1.604 9MS1001272.9531.200.0042.50698.1419 508.133470 5 HS 100 127 2.953 .600 .004 2.506 4 4.5 185 80 6 LS 80 76 3.543 4.000 .003 1.444 20 20.1 1380 30 &4.0 66 MS 80MS100 76 3.543 2.400 .003 1.444 12 11.5 794 50953.5431.600.0042.2561311.563270 6 HS 100 95 3.543 .800 .004 2.256 6 6.3 349 80 y VFX6 (Metric Standard) (inch) Chip Removal Estimated Expected Tool Life Work Material DC Number of Chip vc(mm)FlutesBreaker(SFM)n(min-1)apmaxaefz vf(IPT)(IPM)Rate Cutting Power Torque RatioQPC (inch3/min) (HP) (lbf-ft) (%) S 4 LS 130 200 2.362 2.480 .004 3.153 18 17.8 468 40 &63 44 MS 165 254 2.362 1.488 .004 4.002 14 12.7 263 60MS1953002.362.992.0044.729119.616880 4 HS 195 300 2.362 .496 .005 5.675 7 6.2 109 100 5 LS 130 158 2.953 3.150 .004 3.104 29 27.7 923 40 Titanium Alloy(Ti6Al4V)&80 55 MS 165 200 2.953 1.890 .004 3.939 22 19.8 520 60MS1952362.9531.260.0044.6551714.933280 5 HS 195 236 2.953 .630 .005 5.586 10 9.7 215 100 6 LS 130 126 3.543 3.937 .004 2.979 42 39.3 1637 40 &100 66 MS 165 160 3.543 2.362 .004 3.782 32 28.1 923 60MS1951893.5431.575.0044.4692521.259080 6 HS 195 189 3.543 .787 .005 5.363 15 13.8 382 100 L 4 LS 80 123 2.362 2.480 .003 1.552 9 9.1 389 30 &63 44 MS 80 123 2.362 1.488 .003 1.552 5MS1001542.362.992.0042.42565.2223 505.217870 4 HS 100 154 2.362 .496 .004 2.425 3 2.9 98 80 5 LS 80 97 2.953 3.150 .003 1.528 14 14.1 766 30 Titanium Alloy(Ti-5553)&80 55 MS 80 97 2.953 1.890 .003 1.528 9MS1001212.9531.260.0042.38798.1440 508.135070 5 HS 100 121 2.953 .630 .004 2.387 4 4.5 194 80 6 LS 80 78 3.543 3.937 .003 1.467 20 20.1 1358 30 &100 66 MS 80MS100 78 3.543 2.362 .003 1.467 12 11.5 781 50973.5431.575.0042.2921311.562270 6 HS 100 97 3.543 .787 .004 2.292 6 6.3 344 80 Note 1) Please note that machining performance varies depending to the conditions such as machine rigidity, work clamping rigidity, coolant supply system, pressure and flow volume etc. Note 2) Internal coolant is recommended. Please use an FMH type arbor for through coolant. Using external coolant in combination with through coolant is even more effective. Note 3) The tool life ratio shows the standard when ae = tool diameter × 20% is assumed to be 100 when shoulder cutting. Note 4) The maximum depth of cut (apmax) varies according to the machine rigidity and power. L193 INDEXABLE MILLING