Общий каталог Mitsubishi 2020 - 2021 - страница 1341

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

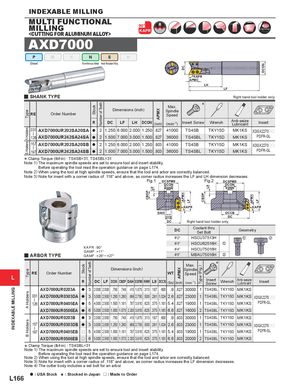

INDEXABLE MILLING

TypeB Holders A HoldersTypeA HoldersB Holders

────

Stock

Number of Teeth

Stock

Number of Teeth

CBDP

L8

APMX

APMX

DCAPMX

LF

CBDPType (Fig.)

L8

APMX

LF

DCON

INDEXABLE MILLING

MULTI FUNCTIONALMILLING