Общий каталог Mitsubishi 2020 - 2021 - страница 1330

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

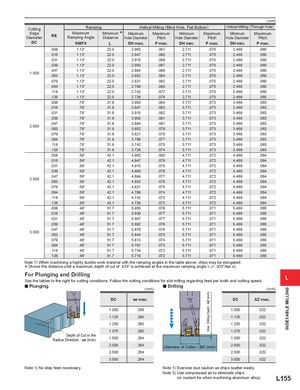

( inch) Cutting Ramping Helical Milling (Blind Hole, Flat Bottom) Helical Milling (Through Hole) EdgeDiameterRE MaximumRamping AngleMinimum Distance * Maximum Hole Diameter MaximumPitch MinimumHole DiameterMaximumPitch MinimumHole DiameterMaximumPitch DC RMPX L DH max. P max. DH min. P max. DH min. P max. .008 1.13° 22.0 2.963 .091 2.711 .075 2.469 .060 .016 1.13° 22.0 2.947 .090 2.711 .075 2.469 .060 .031 1.13° 22.0 2.915 .088 2.711 .075 2.469 .060 .039 1.13° 22.0 2.900 .087 2.711 .075 2.469 .060 1.500 .047.063 1.13°1.13° 22.0 2.884 .086 2.711 .075 2.469 .06022.02.852.0842.711.0752.469.060 .079 1.13° 22.0 2.821 .082 2.711 .075 2.469 .060 .094 1.13° 22.0 2.789 .080 2.711 .075 2.469 .060 .118 1.13° 22.0 2.742 .077 2.711 .075 2.469 .060 .126 1.13° 22.0 2.726 .076 2.711 .075 2.469 .060 .008 .78° 31.8 3.963 .084 3.711 .073 3.469 .063 .016 .78° 31.8 3.947 .083 3.711 .073 3.469 .063 .031 .78° 31.8 3.915 .082 3.711 .073 3.469 .063 .039 .78° 31.8 3.900 .081 3.711 .073 3.469 .063 2.000 .047.063 .78°.78° 31.8 3.884 .081 3.711 .073 3.469 .06331.83.852.0793.711.0733.469.063 .079 .78° 31.8 3.821 .078 3.711 .073 3.469 .063 .094 .78° 31.8 3.789 .077 3.711 .073 3.469 .063 .118 .78° 31.8 3.742 .075 3.711 .073 3.469 .063 .126 .78° 31.8 3.726 .074 3.711 .073 3.469 .063 .008 .59° 42.1 4.963 .080 4.711 .072 4.469 .064 .016 .59° 42.1 4.947 .079 4.711 .072 4.469 .064 .031 .59° 42.1 4.915 .078 4.711 .072 4.469 .064 .039 .59° 42.1 4.900 .078 4.711 .072 4.469 .064 2.500 .047.063 .59°.59° 42.1 4.884 .077 4.711 .072 4.469 .06442.14.852.0764.711.0724.469.064 .079 .59° 42.1 4.821 .075 4.711 .072 4.469 .064 .094 .59° 42.1 4.789 .074 4.711 .072 4.469 .064 .118 .59° 42.1 4.742 .073 4.711 .072 4.469 .064 .126 .59° 42.1 4.726 .072 4.711 .072 4.469 .064 .008 .48° 51.7 5.955 .078 5.711 .071 5.469 .065 .016 .48° 51.7 5.939 .077 5.711 .071 5.469 .065 .031 .48° 51.7 5.907 .077 5.711 .071 5.469 .065 .039 .48° 51.7 5.892 .076 5.711 .071 5.469 .065 3.000 .047.063 .48°.48° 51.7 5.876 .076 5.711 .071 5.469 .06551.75.844.0755.711.0715.469.065 .079 .48° 51.7 5.813 .074 5.711 .071 5.469 .065 .094 .48° 51.7 5.781 .073 5.711 .071 5.469 .065 .118 .48° 51.7 5.734 .072 5.711 .071 5.469 .065 .126 .48° 51.7 5.718 .072 5.711 .071 5.469 .065 Note 1) When machining a highly ductile work material with the ramping angles in the table above, chips may be elongated. * Shows the distance until a maximum depth of cut of .433” is achieved at the maximum ramping angle L (= .433”/tan α). For Plunging and DrillingSee the tables to the right for cutting conditions. Follow the cutting conditions for slot milling regarding feed per tooth and cutting speed. L a Plunging ( inch) a Drilling ( inch) DC ae max. DC AZ max. 1.000 .256 1.000 .022 1.125 .260 1.125 .022 1.250 .260 1.250 .022 1.375 .260 1.375 .022 Depth of Cut in theRadius Direction : ae (inch)1.500.264 1.500 .022 2.000 .264 Diameter of Cutter : DC (inch) 2.000 .022 2.500 .264 2.500 .022 3.000 .264 3.000 .022 Note 1) No step feed necessary. Note 1) Exercise due caution as chips scatter easily. Note 2) Use compressed air to eliminate chips (or coolant for when machining aluminum alloy). L155 Max. Drilling Depth : AZ (inch) INDEXABLE MILLING