Общий каталог Mitsubishi 2020 - 2021 - страница 1262

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

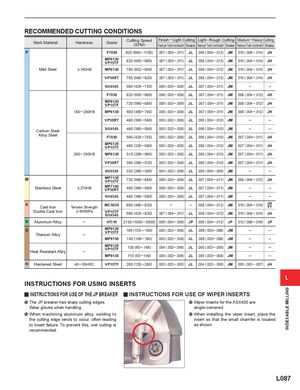

RECOMMENDED CUTTING CONDITIONS Work Material Hardness Grade Cutting Speed Finish ─ Light Cutting Light─Rough Cutting Medium ─ Heavy Cutting(SFM)Feed per Tooth (inch/tooth)BreakerFeed per Tooth (inch/tooth)BreakerFeed per Tooth (inch/tooth)Breaker P F7030 920 (690─1150) .007 (.003─.011) JL .008 (.004─.012) JM .010 (.008─.014) JH MP6120VP15TF 820 (655─985) .007 (.003─.011) JL .008 (.004─.012) JM .010 (.004─.014) JH Mild Steel < 180HB MP6130 780 (652─950) .007 (.003─.011) JL .008 (.004─.012) JM .010 (.004─.014) JH VP30RT 755 (590─920) .007 (.003─.011) JL .008 (.004─.012) JM .010 (.004─.014) JH NX4545 590 (425─ 755) .006 (.003─.009) JL .007 (.004─.011) JM ─ ─ F7030 820 (655─ 985) .006 (.003─.009) JL .007 (.004─.011) JM .008 (.004─.012) JH MP6120VP15TF 720 (560─885) .006 (.003─.009) JL .007 (.004─.011) JM .008 (.004─.012) JH 180 ─ 280HB MP6130 600 (480─740) .006 (.003─.009) JL .007 (.004─.011) JM .008 (.004─.012) JH VP30RT 490 (395─590) .005 (.002─.008) JL .006 (.004─.010) JM ─ ─ Carbon Steel NX4545 490 (390─ 590) .005 (.002─.008) JL .006 (.004─.010) JM ─ ─ Alloy Steel F7030 590 (425─ 755) .005 (.002─.008) JL .006 (.004─.010) JM .007 (.004─.011) JH MP6120VP15TF 460 (330─590) .005 (.002─.008) JL .006 (.004─.010) JM .007 (.004─.011) JH 280 ─ 350HB MP6130 510 (290─560) .005 (.002─.008) JL .006 (.004─.010) JM .007 (.004─.011) JH VP30RT 390 (260─525) .005 (.002─.008) JL .006 (.004─.010) JM .007 (.004─.011) JH NX4545 330 (260─ 395) .004 (.002─.006) JL .005 (.004─.008) JM ─ ─ M MP7130VP15TF 720 (560─885) .006 (.003─.009) JL .007 (.004─.011) JM .008 (.004─.012) JH Stainless Steel < 270HB MP7140VP30RT 490 (395─590) .006 (.003─.009) JL .007 (.004─.011) JM ─ ─ NX4545 490 (390─ 590) .006 (.003─.009) JL .007 (.004─.011) JM ─ ─ K Cast Iron Tensile Strength MC5020 655 (490─820) ─ ─ .008 (.004─.012) JM .010 (.004─.014) JHFT Ductile Cast Iron < 450MPa VP15TFNX4545 590 (425─ 820) .007 (.004─.011) JL .008 (.004─.012) JM .010 (.004─.014) JH N Aluminum Alloy ─ HTi10 2130 (1000 ─3300) .006 (.004─.008) JP .008 (.004─.012) JP .012 (.008─.016) JP S Titanium Alloy ─ MP9120VP15TF165 (130 ─ 195) .005 (.002─.008) JL .006 (.003─.009) JM ─ ─ MP9130 140 (100─ 180) .005 (.002─.008) JL .006 (.003─.009) JM ─ ─ Heat Resistant Alloy ─ MP9120VP15TF 130 (65─165) .004 (.002─.006) JL .005 (.003─.008) JM ─ ─ MP9130 110 (55─140) .004 (.002─.006) JL .005 (.003─.008) JM ─ ─ H Hardened Steel 40 ─ 55HRC VP15TF 200 (120─280) .003 (.002─.005) JL .004 (.002─.006) JM .005 (.003─.007) JH L INSTRUCTIONS FOR USING INSERTS y INSTRUCTIONS FOR USE OF THE JP BREAKER y INSTRUCTIONS FOR USE OF WIPER INSERTS a The JP breaker has sharp cutting edges. a Wiper inserts for the ASX400 are Wear gloves when handling. single-cornered. a When machining aluminum alloy, welding to a When installing the wiper insert, place the the cutting edge tends to occur, often leading insert so that the small chamfer is located to insert failure. To prevent this, wet cutting is as shown. recommended. L087 INDEXABLE MILLING